WHO WE ARE

SINOTOP FENCE is a supplier and factory of industrial mesh and fencing. Whether you are a government agency, an end user, or an industrial facility, our mission is to safeguard your assets. We aim to become our clients’ reliable partners by offering the greatest goods, services, and solutions. This vision is realized through a focus on collaborative customer relationships, quality excellence, and innovation.

We offer a comprehensive range of fence products, including steel barriers for special events, temporary and permanent fencing for construction sites, associated parts, and more, in our full product line. Our manufacturing follows the ISO system requirements for operation and auditing. The products have a 20-year warranty.

Shanghai, Qingdao, and Tianjin, China’s three main ports, are all close to our warehouse. Our wide choice of products and first-rate logistics can help ensure maximum safety on your construction site, during road construction, or at any event.

Why Choose Us

From design to delivery, we offer professional support, high standards, and flexible cooperation to meet your project needs.

Free Design

The professional and high-efficiency technical team can provide customers with FREE design services to help develop new products.

International Standards

All the fence panels, gates, and accessories material and production are made by international standards.

One-Stop-Purchasing

Customers can get all related products with high quality, competitive prices, quick delivery, and excellent service.

Quick Delivery

10 containers per day can be shipped with full inventory in our warehouse.

Partnership

We are not only a supplier but also a designer and long-term partner for our customers.

Favourable Payment

We offer favourable and flexible payment terms for customers to build a win-win partnership.

Our Manufacturing Equipment

Galvanised Pipe Raw Material

- Having extensive use.

- Easy to acquire.

- Low cost.

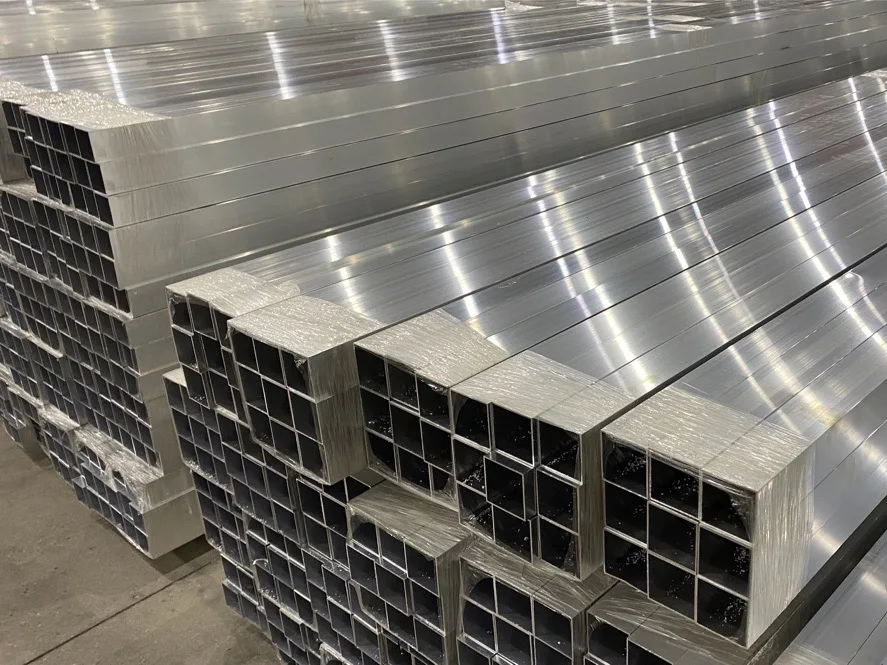

Aluminum Alloy Raw Material

- Excellent corrosion-resistant performance.

- Low metal density, lightweight.

- Easy to install.

- Strong plasticity, and good productivity.

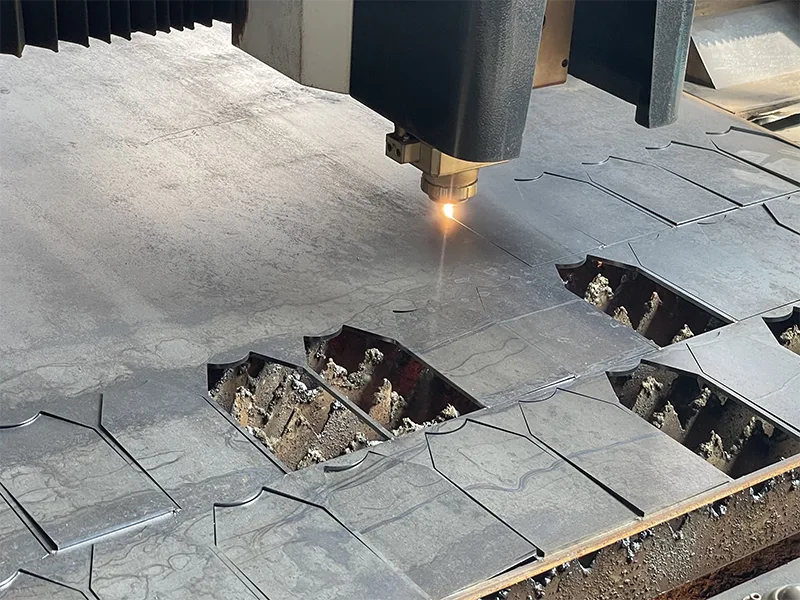

Laser Cutting Machine

- Production of complex patterns.

- Smooth cutting surface.

- Meet customers’ special customization requirements.

Automatic Punching Machine

- More accurate than manual punching.

- Smooth punching surface.

- More standard punching size.

Stamping Press Machine

- High-efficiency production.

- Precise stamping process.

- Automated operation mode.

Profile Rolling Machine

- More efficient production.

- CNCmachine with accuracy and consistency.

Manual Welding

- improve production efficiency.

- Guarantee welding quality.

- Strong adaptability.

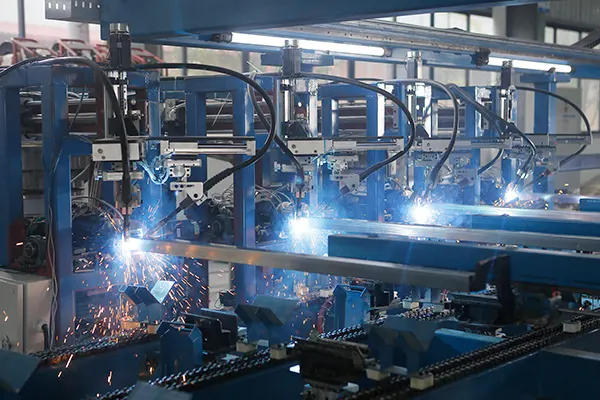

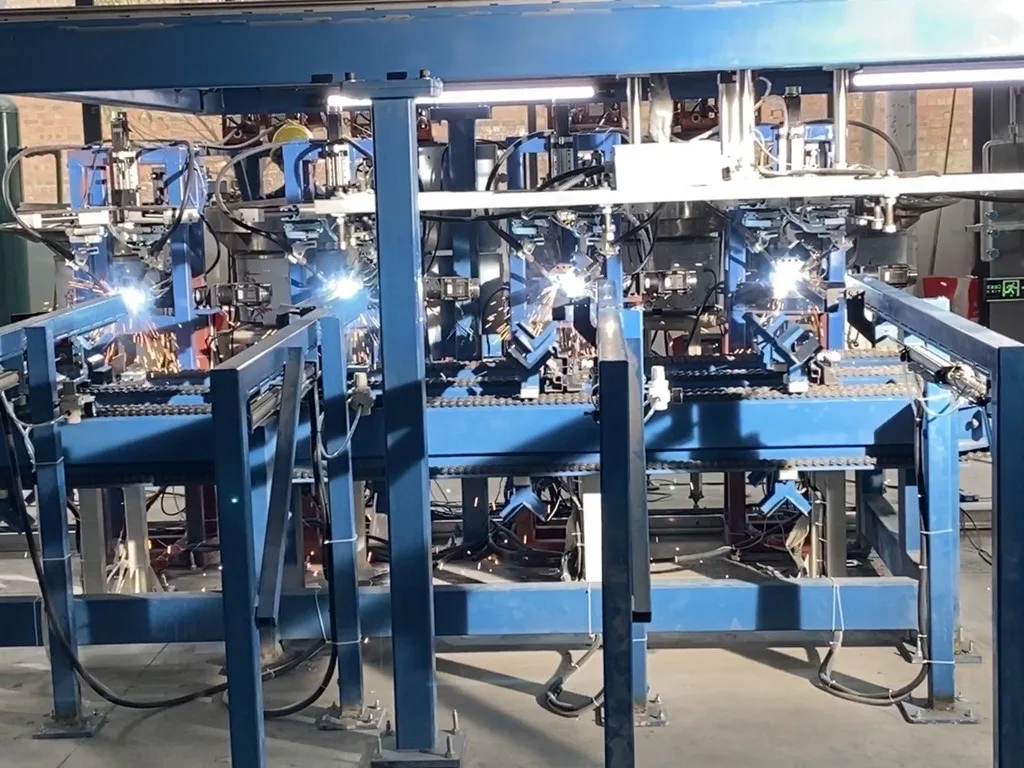

Robot Weld Machine

- Stable welding quality.

- Fast welding speed.

- Short production cycle.

Electro Galvanizing Production Line

- Good coating quality.

- Simple process flow.

- Easy to operate.

Hot-dip Galvanised Pipe Production Line

- High production efficiency.

- Simple operation and maintenance.

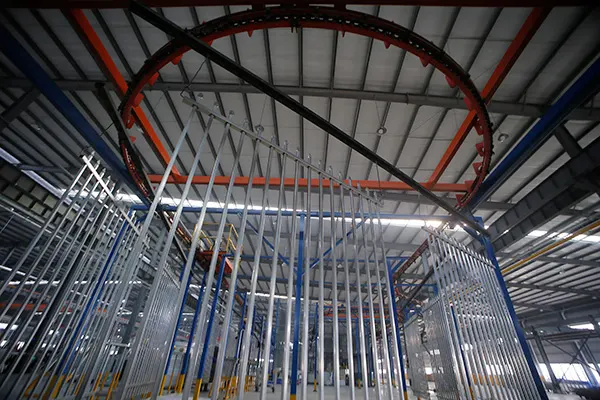

Powder coated Line

- Makes coating non-blind area.

- Surface smooth, with no wrinkles or burr.

- Strongadhesion to the metal surface.

Package

- Protection products.

- Enhance brand image.

- Convenient transportationand storage.

Our Fence Product Production Process

Each step of our production process — from raw material selection, wire drawing, welding, and coating, to packaging — is performed with meticulous attention to detail. Our advanced equipment and skilled technicians guarantee consistent quality, long-lasting performance, and excellent surface finishing in every product we deliver.

1 Order Confirmation

After receiving the customer’s order, we verify product specifications, quantities, and delivery requirements to ensure accuracy.

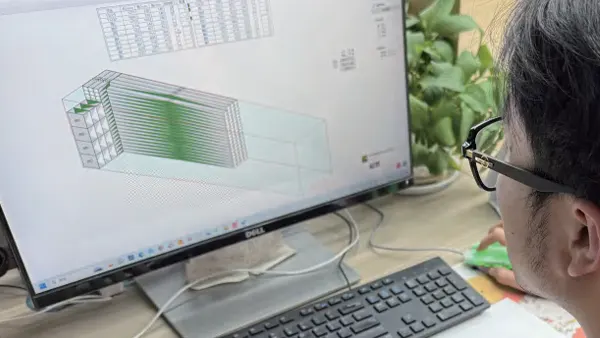

2 Design & 3D Modeling

Our engineers create CAD drawings and 3D models to visualize the fence design and structure before production.

3 Sample Production

We quickly produce physical samples for customer approval, allowing adjustments before mass production.

4 Material Preparation

High-quality metal raw materials are selected, cut, and prepared according to design specifications.

5 Welding & Fabrication

The fence components are precisely welded and fabricated to form panels, gates, or other structures.

6 Surface Treatment

Products undergo galvanization, powder coating, or painting to ensure durability and corrosion resistance.

7 Quality Inspection

Every batch is carefully checked for dimensions, weld quality, surface finish, and overall standards.

8 Packaging & Labeling

Products are securely packed to prevent damage during transportation, with clear labeling for identification.

9 Shipping & Delivery

Orders are arranged for shipment via container or logistics service, ensuring timely delivery to the customer.