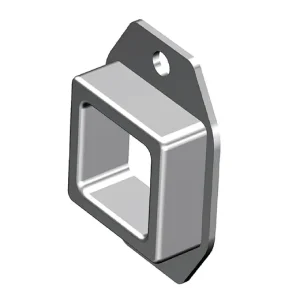

Corrosion-Resistant Design

The pressed steel features a black polypropylene coating that effectively resists UV rays, salt spray, and chemical erosion, making it ideal for coastal, industrial, or harsh environments.

Weld-Free Installation

With pre-drilled holes and self-tapping screws, securing the rails to the posts takes just one minute and requires no specialized tools.

Concealed Structural Profile

The 2¾-inch matte-black brackets completely hide the inside rails, ensuring a sleek and streamlined appearance for your fence.

Versatile Compatibility

Designed to work with 1″square rails and 2″square posts, this system easily integrates with steel, aluminum, or decorative fencing options.

Bidirectional Load-Bearing

The dual brackets and fasteners provide support for right-angle or sloped offering flexibility for complex terrains.

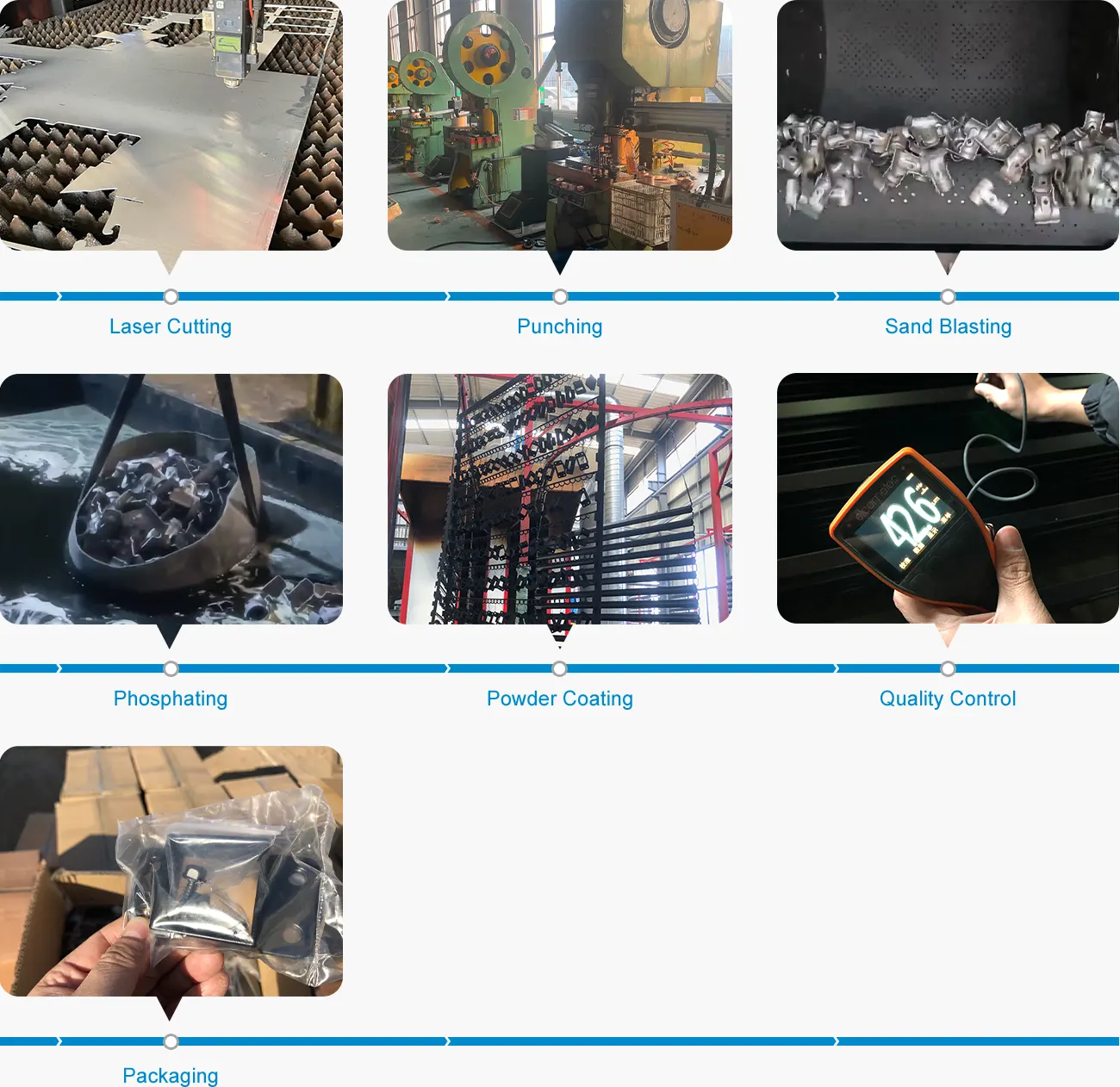

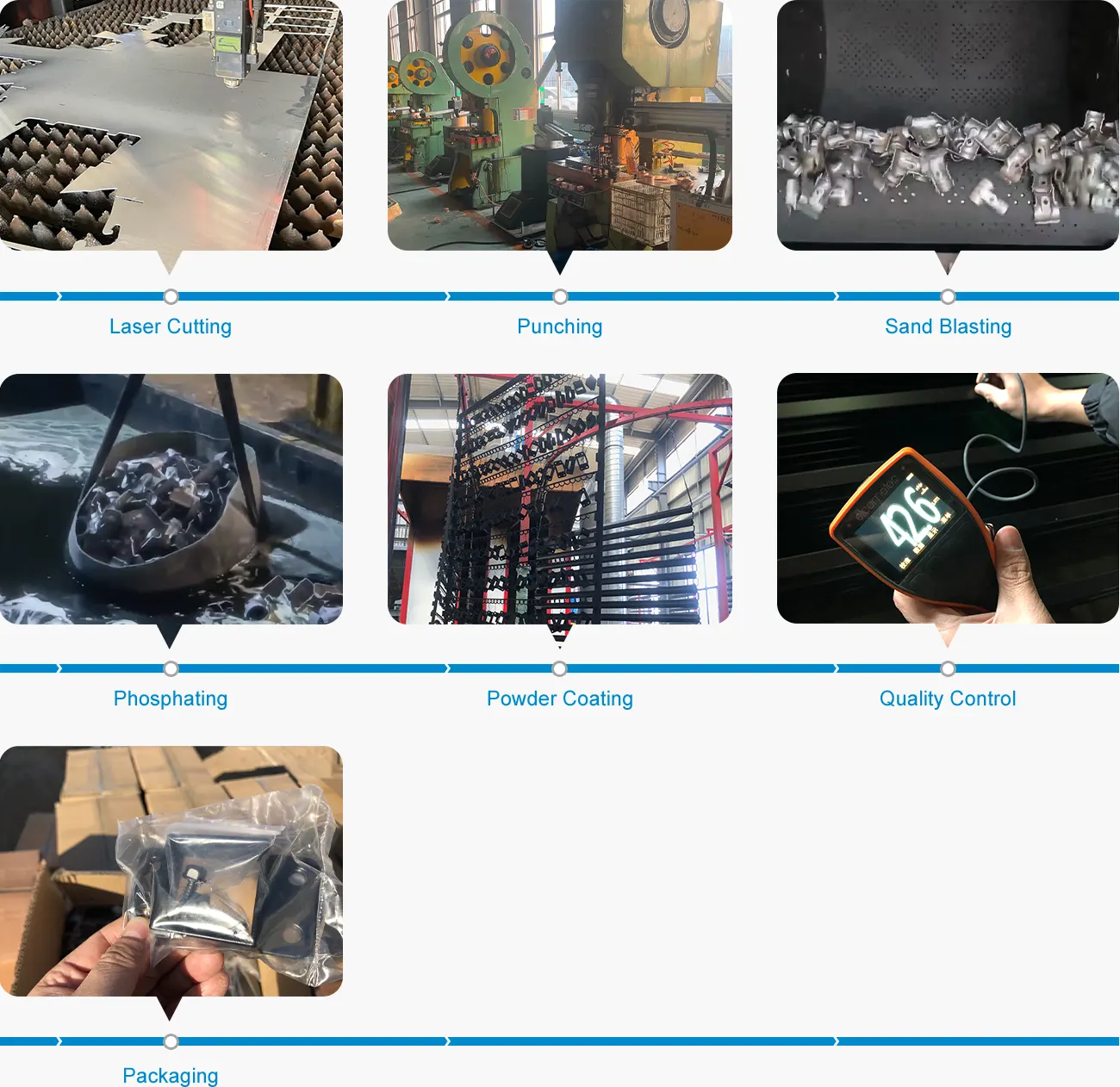

Flat Wall Mount Bracket Production Process

Laser Cutting

A laser cutter is used to precisely cut sheet metal. The material is cut into the desired shape and size according to the design drawings.

Punching

After cutting, the stamping process begins. A punch press and die are used to punch or form the metal part to meet subsequent assembly and functional requirements.

Sand Blasting

After stamping, the metal part may have burrs and an oxide layer on its surface, so sandblasting is necessary. Sandblasting effectively removes surface impurities and increases surface roughness, ensuring good adhesion for subsequent painting.

Phosphating

After sandblasting, the metal part undergoes phosphating. Phosphating forms a protective film on the metal surface, enhancing corrosion resistance and adhesion.

Powder Coating

After phosphating, the metal part proceeds to the powder coating process. Electrostatic spraying is used to evenly apply the powder coating to the metal surface. After spraying, the metal parts enter a baking oven for curing, ensuring a strong bond between the coating and the metal surface.

Quality Control

Quality control is crucial throughout the entire production process. After each step, rigorous quality checks are conducted, including dimensional measurements, surface finish quality, and coating thickness. The final product also undergoes functional testing to ensure it meets design requirements and usage standards.

Packaging

Painted parts that pass quality inspection are packaged. The packaging material is moisture-proof and shock-resistant to ensure product safety during transportation.

Flat Mount Bracket Application

- As an important accessory of the fence solutions, it needs to be used with the fence panel system.

- Suitable for Stadiums, Retail Outlets, Housing, Gardens, Institutions, Manufacturing, Parks & Recreation, etc.

Black Universal Flat Mount Bracket Packaging

- Flat mount brackets are typically individually wrapped in plastic film first, then packaged in cartons or wooden cases.

- We can customize to meet specific customer requirements, including the option to add a printed logo or barcode.

- Packing cartons on the outside ensures safe transportation during logistics.

- If you have other needs, we will pack them strictly according to your requirements.

- We use sea shipping, which is convenient, fast, and stable.