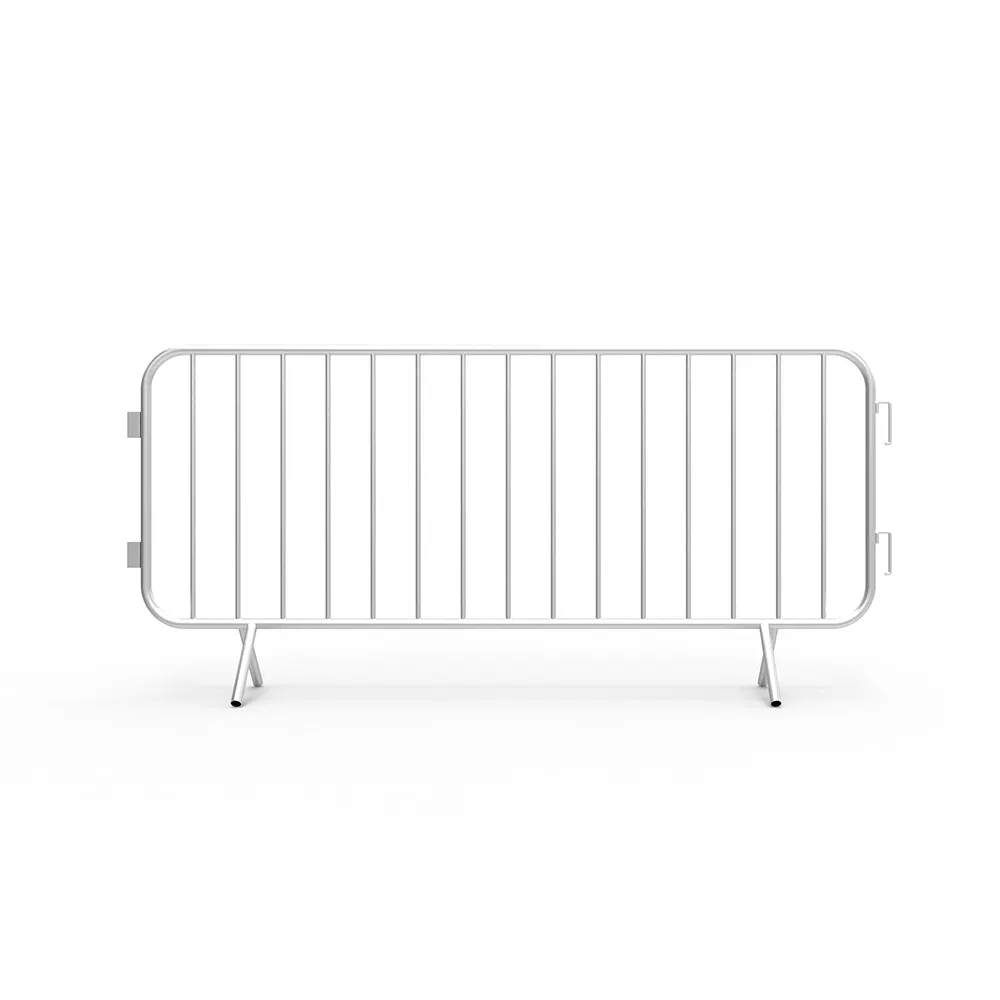

Sinotop Fence’s fixed-leg crowd control barrier is a highly effective product designed for crowd management and safe zone demarcation. Widely used in scenarios such as sporting events and crowd management, it effectively manages crowd flow and demarcates areas, ensuring safety. This barrier’s unique V-shaped fixed-leg design provides exceptional stability and adapts to various surface conditions, ensuring increased safety during use.

Our strict control over the production process of our fixed-leg crowd control barrier makes it one of the most durable safety barriers on the market. We use high-quality mild steel as the manufacturing material, ensuring its sturdiness and durability. The frame and internal joints are fully welded to ensure a secure overall structure. We also use powder coating or galvanizing to enhance the barrier’s rust and oxidation resistance.

As a professional fence manufacturer, our products are available in a variety of sizes to meet diverse application needs. We can also customize specifications, materials, and craftsmanship to ensure the best user experience.

| Length | 7.5′ | 7.5′ | 6.5′ or 8′ |

| Height | 43.3″ | 43.3″ | 38″ or 44″ Adjustable |

| Tube Diameter NPS | 1.5″ | 1.5″ | 1.25″ |

| Tube Gauge BWG | 20 (0.035″) | 20 (0.035″) | 16 (0.065″) |

| Weight | 23.5 lbs. | 20.5 lbs. | 51 lbs. or 56lbs. |

| Per Pallet | 18 Barriers | 20 Barriers | 25 Barriers |

| Material | Pre-Galvanized Carbon Steel | Pre-Galvanized Carbon Steel | Galvanized Carbon Steel |

| Coating Finish | Zinc Electroplated | Zinc Electroplated | Zinc Hot Dipped |

Select high-quality galvanized steel pipe as the primary material to ensure its corrosion resistance and strength. Inspect the material to ensure it meets production standards, including thickness, diameter, and uniformity of the galvanized coating.

Determine the length and quantity of each component according to the design drawings. Use a cutting machine to cut the steel pipe to the required length, ensuring a smooth cut surface and avoiding burrs.

Use the equipment to pre-punch holes in the pipe to facilitate subsequent operations.

Determine the locations and angles of the pipe to be bent according to the design requirements. Use a pipe bending machine to bend the steel pipe to the desired shape, ensuring accurate bend angles and no cracks.

Pre-galvanized steel pipes are welded into the panel frame using sophisticated welding techniques.

Cleaning and roughening the surface by spraying high-speed abrasive particles. It can remove impurities such as rust, oil, and scale.

The phosphating film itself has a certain anti-corrosion ability and can provide excellent adhesion of paint, powder coating, or other organic coatings.

We will conduct a quality inspection on each product to check the strength, wall thickness, and powder coating thickness to ensure the quality stability of each product.

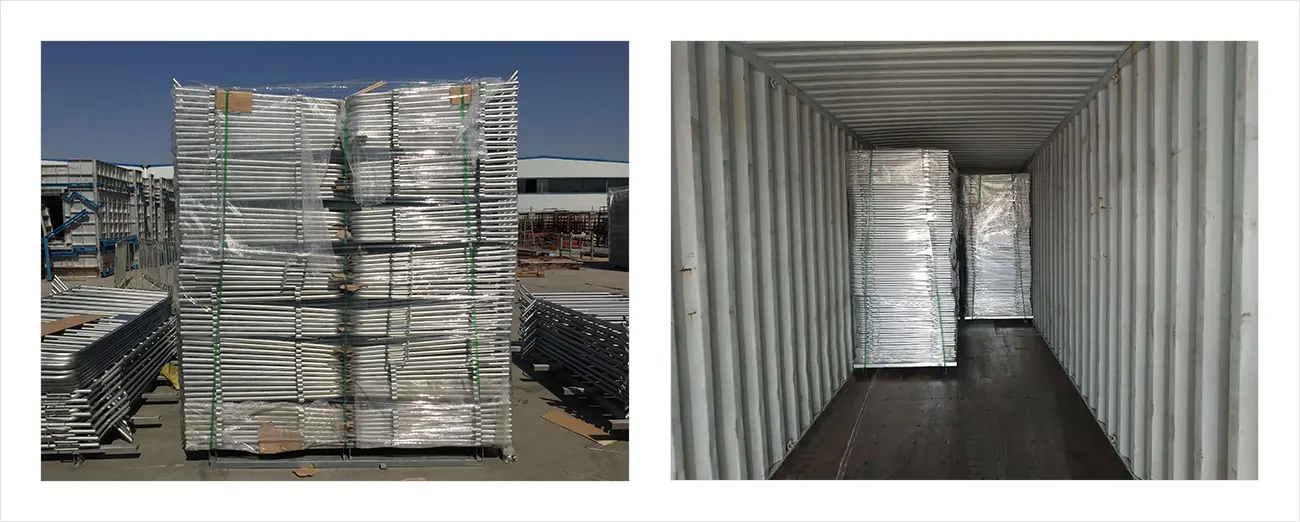

Professional transportation methods ensure the safe transportation of products.

For small orders, sample orders, or air shipments, T/T in advance (telegraphic transfer-bank order). We can also offer preferential and flexible payment terms to our customers to establish a win-win partnership. Other payments: L/C, D/A, D/P, MoneyGram, Paypal, or Escrow. There can be minor variations in different places.

We offer the following post-purchase services following your payment:

We have the best after-sales staff around. Please Contact Us as soon as possible if you experience any after-sale issues. We’ll get back to you as soon as we can with a satisfying answer.