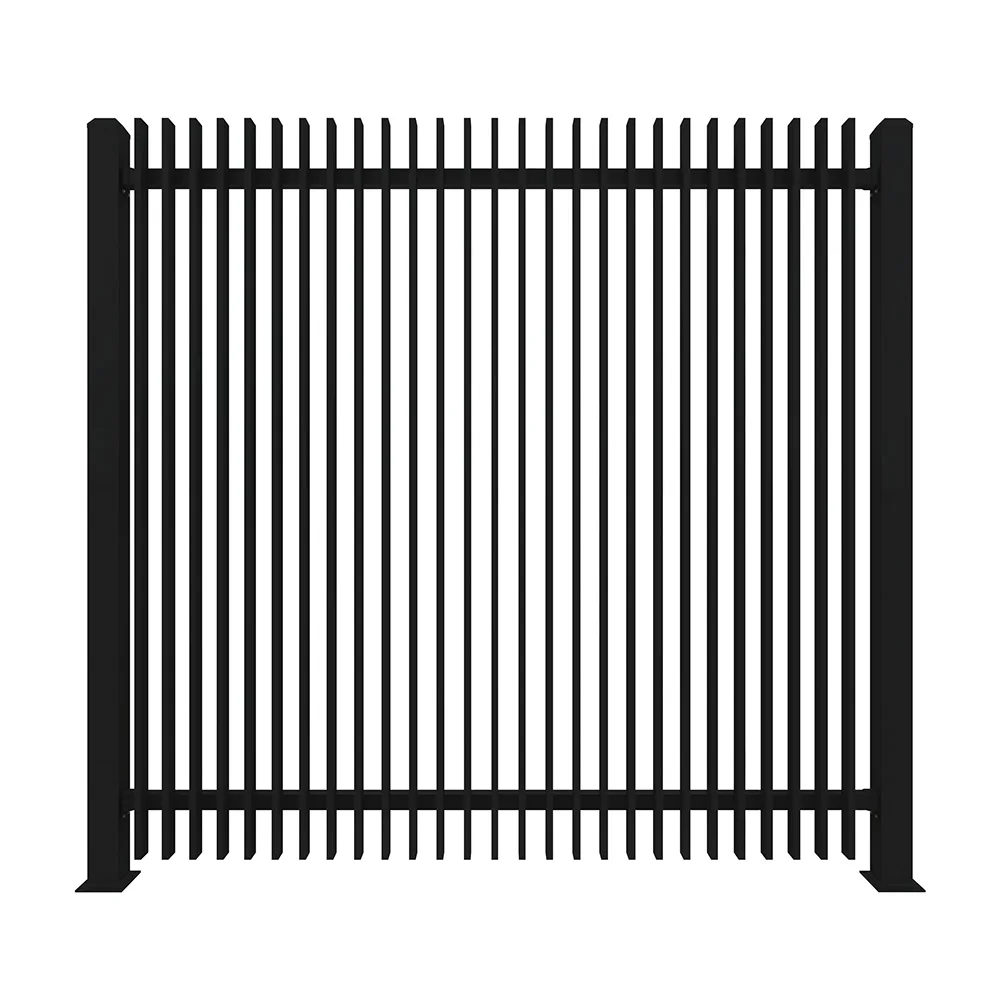

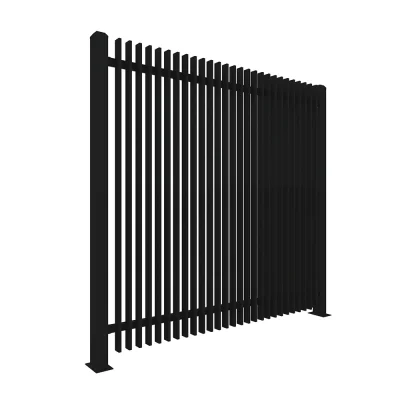

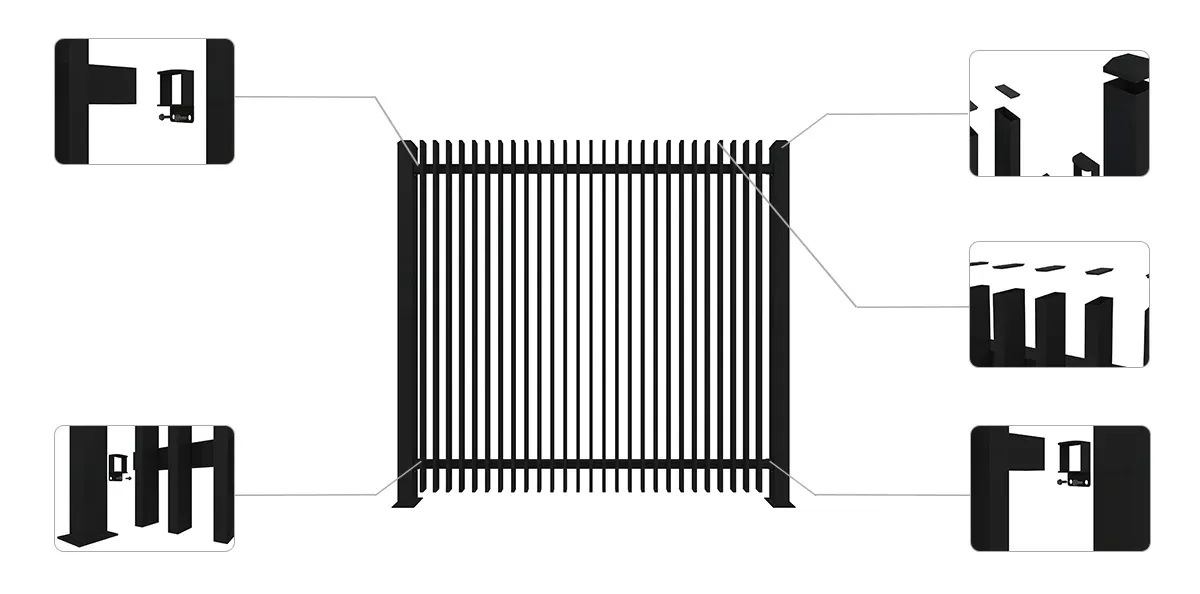

The Vertical Blade Fence serves as a striking decorative element in contemporary architectural designs. By positioning the panels closely together, it effectively emphasizes the vertical lines of a house, creating a visually captivating effect.

One of its significant advantages is its durability. Unlike wood, which is prone to fading and warping over time, the Vertical Blade Fence boasts a longer service life. Its unique vertical blade fence design structure sets it apart from other products on the market, endowing it with a distinct and eye-catching shape.

This innovative and minimalist design not only gives the fence a one-of-a-kind appearance but also contributes to its growing popularity. Moreover, the fence provides a reliable level of security, safeguarding the property within the enclosed area.

The application scope of this product is extensive. It is well-suited for various settings, including industrial areas, commercial zones, and other safety-protection scenarios, making it a versatile choice for different needs.

Typically, our metal vertical blade fence is crafted from steel, which ensures high strength and long-term durability. However, customers also have the option to choose from other materials such as aluminum and stainless steel. In terms of surface treatment, the fence undergoes powder-spraying or hot-dip galvanizing processes, enhancing its performance and resistance to corrosion.

We offer our products in a wide range of sizes. As a professional Aluminum Blade Fencing Manufacturer, we take pride in our ability to customize products according to specific requirements and usage scenarios. Whether it’s for a large-scale industrial project or a small-scale commercial property, we can tailor the fence to meet your exact needs.

| Panel Size (Height * Width) | 900mm*2200mm |

| 1000mm*1700mm | |

| 1200mm*2200mm | |

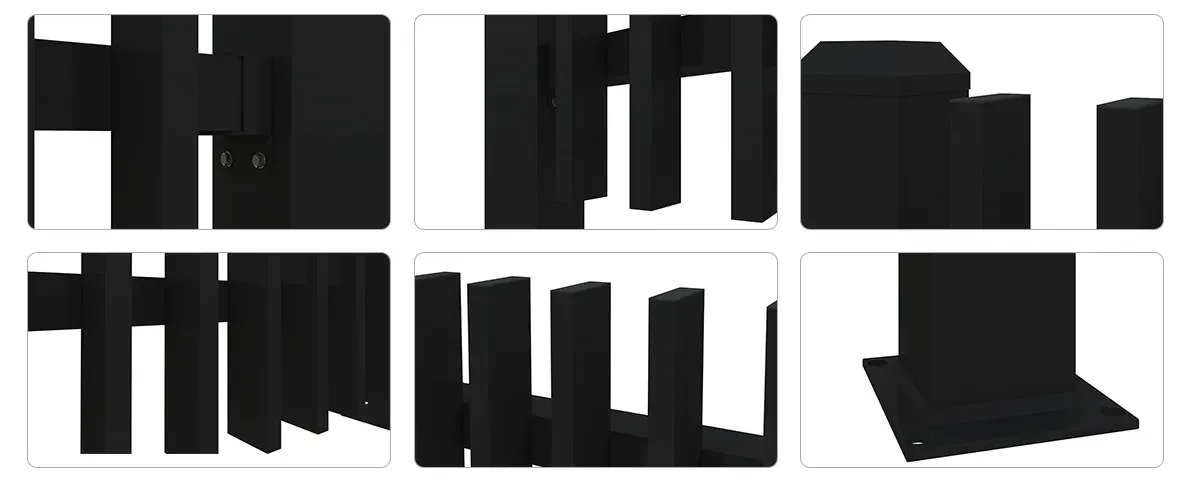

| Rail | 40x40x2.4mm |

| Blade | 50mmx16mm RHS Vertical Blade Gap: 50mm |

| Fittings | Each picket has a plastic cap |

| Material | Galvanized Steel |

| Color | Black, Customized Colors |

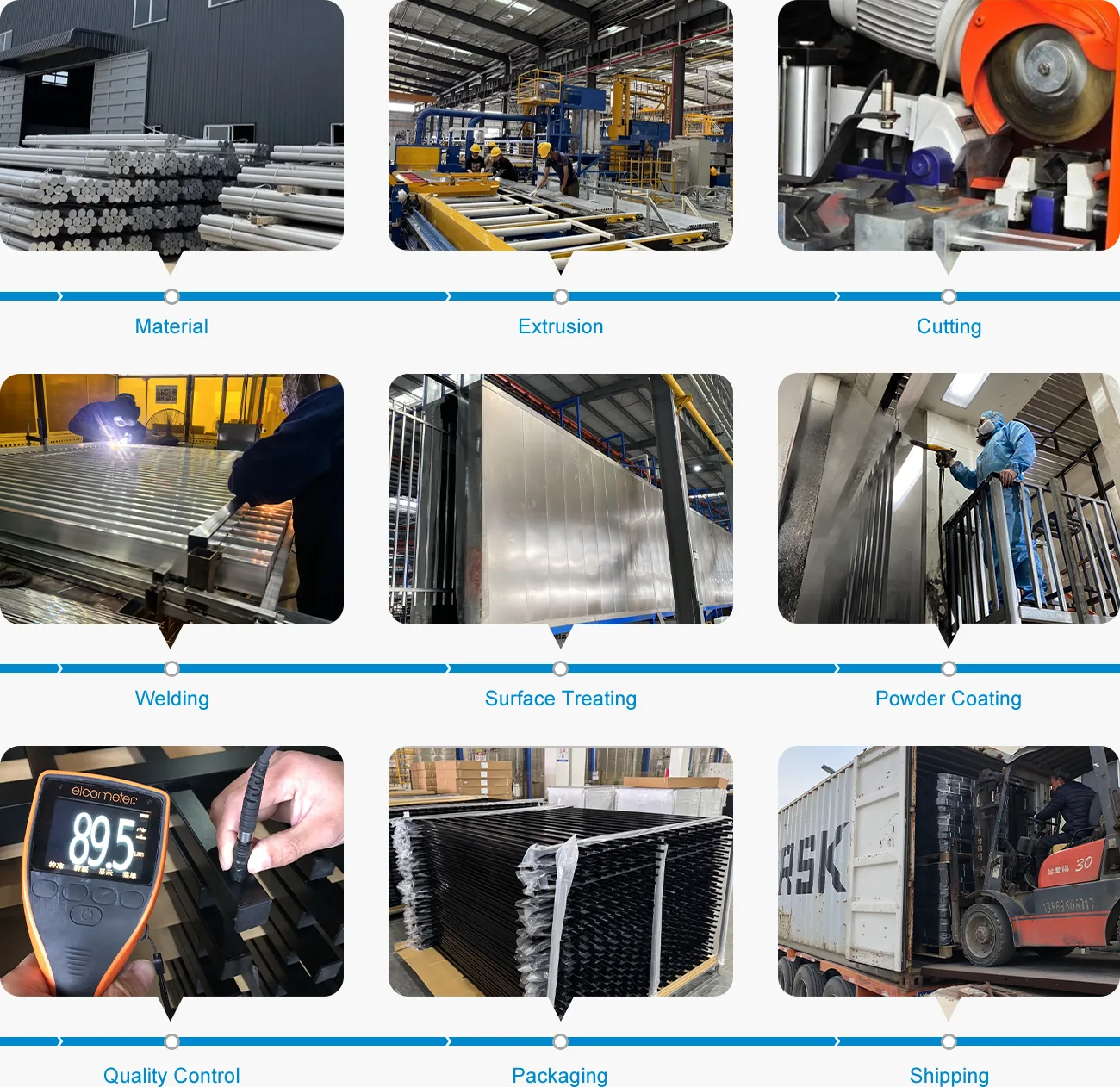

Material Inspection: Check whether the outer diameter and wall thickness of the pipe meet the requirements of the metal vertical blade fence drawing, thus ensuring quality.

Pipe Manufacturing: Cut the pipe to meet the length requirements on the drawing.

Salt Forming: Flatten and straighten the tubing into a salt shape.

Welding: Welding the pre-galvanized steel pipes into the panel frame using sophisticated welding techniques.

Grinding and Polishing: The purpose of this operation is to remove welding slag or other impurities on the surface to facilitate the next step.

Galvanizing: The surface of the vertical slat fence is galvanized to form a dense layer of pits on the surface of the pipe, thereby increasing the adhesion ability of the powder.

Powder Coating: The surface of the product is sprayed with epoxy-polyester powder and cured at high temperatures. This process makes the product’s paint film thickness at least ≥80μm. This process can make the product more rust-proof and corrosion-resistant, so it can withstand the erosion of various harsh environments.

Quality Control: We will conduct a quality inspection on each piece of powder-coating vertical blade fencing. Such as checking the strength, wall thickness, and powder coating thickness to ensure the quality stability of each product. We will be responsible for every product so that customers can get the best quality products.

Packaging: Professional transport methods ensure the safe transportation of products.

Vertical Blade Fence is easy to DIY install, high-quality, long-lasting steel fence solution, perfect for residential and commercial spaces, widely used in villas, swimming pools, gardens, flower beds, lawns, industrial and financial institutions, stadiums, and squares.

For small orders, sample orders, or air shipments, T/T in advance (telegraphic transfer-bank order). We can also offer preferential and flexible payment terms to our customers to establish a win-win partnership. Other payments: L/C, D/A, D/P, MoneyGram, Paypal, or Escrow. There can be minor variations in different places.

We offer the following post-purchase services following your payment:

We have the best after-sales staff around. Please Contact Us as soon as possible if you experience any after-sale issues. We’ll get back to you as soon as we can with a satisfying answer.