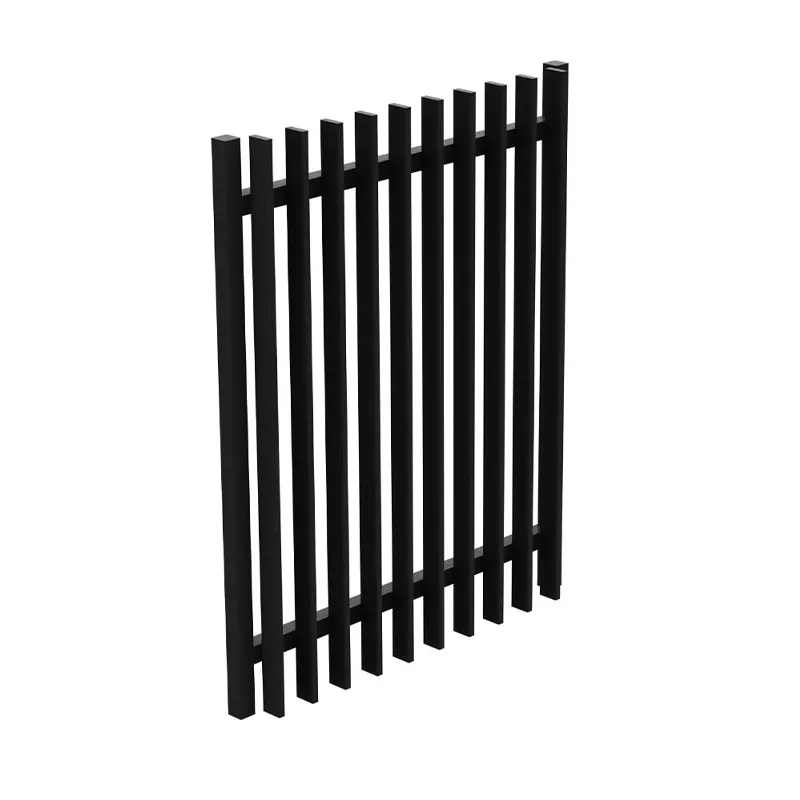

Sinotop Fence’s Blade Fence Gate presents a contemporary architectural fencing solution. Designed to complement Vertical Blade Fence Panels, this gate system merges sleek aesthetics with robust functionality. Featuring vertical aluminum blades measuring 65×16mm, spaced 70mm apart and welded to a 40 × 40mm horizontal crossbar, it creates a clean, three-dimensional profile.

The entire BLADE range is finished with a satin black powder coating, ensuring durability and a modern look that resists fading and corrosion. Engineered for easy installation, the fully welded aluminum gate comes ready to mount, simplifying your fencing project. Its vertical slat design aligns seamlessly with our Blade Fence Panels, enhancing visual consistency while providing added privacy and security.

As a leading manufacturer, we emphasize structural integrity and user-friendly features, making this gate perfect for both DIY enthusiasts and professionals. The Blade Fence Gate strikes a balance between style and practicality, offering a low-maintenance solution for residential gardens, pool enclosures, and commercial properties. Its open design preserves sightlines, allowing natural light to filter through while highlighting the surrounding landscape.

Blade Fence Gate Detail

- Post Caps pre-inserted into pickets & side stiles.

- 70mm gap spacing between pickets.

- 65×16mm RHS pickets face-welded to 40x40x2.4 mm SHS horizontal rails & side stiles.

- 4 weld points per picket.

- Powder-coated finish for longevity.

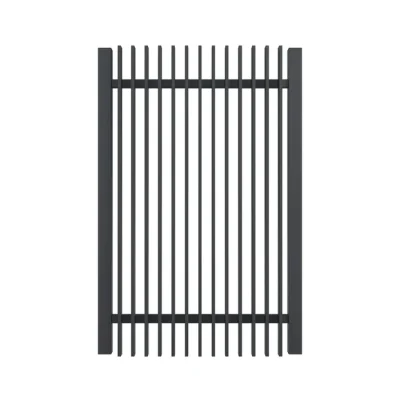

Blade Fence Gate Specifications

| Width(mm) |

1250 |

Height(mm) |

900 |

| 1500 |

1200 |

| 1500 |

1500 |

| 1500 |

1800 |

| Spacing Between Pickets |

70mm |

| Horizontal Top/Bottom |

40×40×2.5mm |

| Vertical picket |

65×16mm |

| Material |

Aluminum or Steel |

| Color |

Black, Custom Color |

| Finish |

Powder Coating |

Product Features

- The pool fence is compliant when installed correctly.

- Caps pre-inserted into pickets & side stiles.

- 70mm gap spacing between pickets.

- 65×16mm RHS pickets face-welded to 40x40x2.4mm SHS horizontal rails & side stiles.

- 4 weld points per picket.

- Powder-coated finish for longevity.

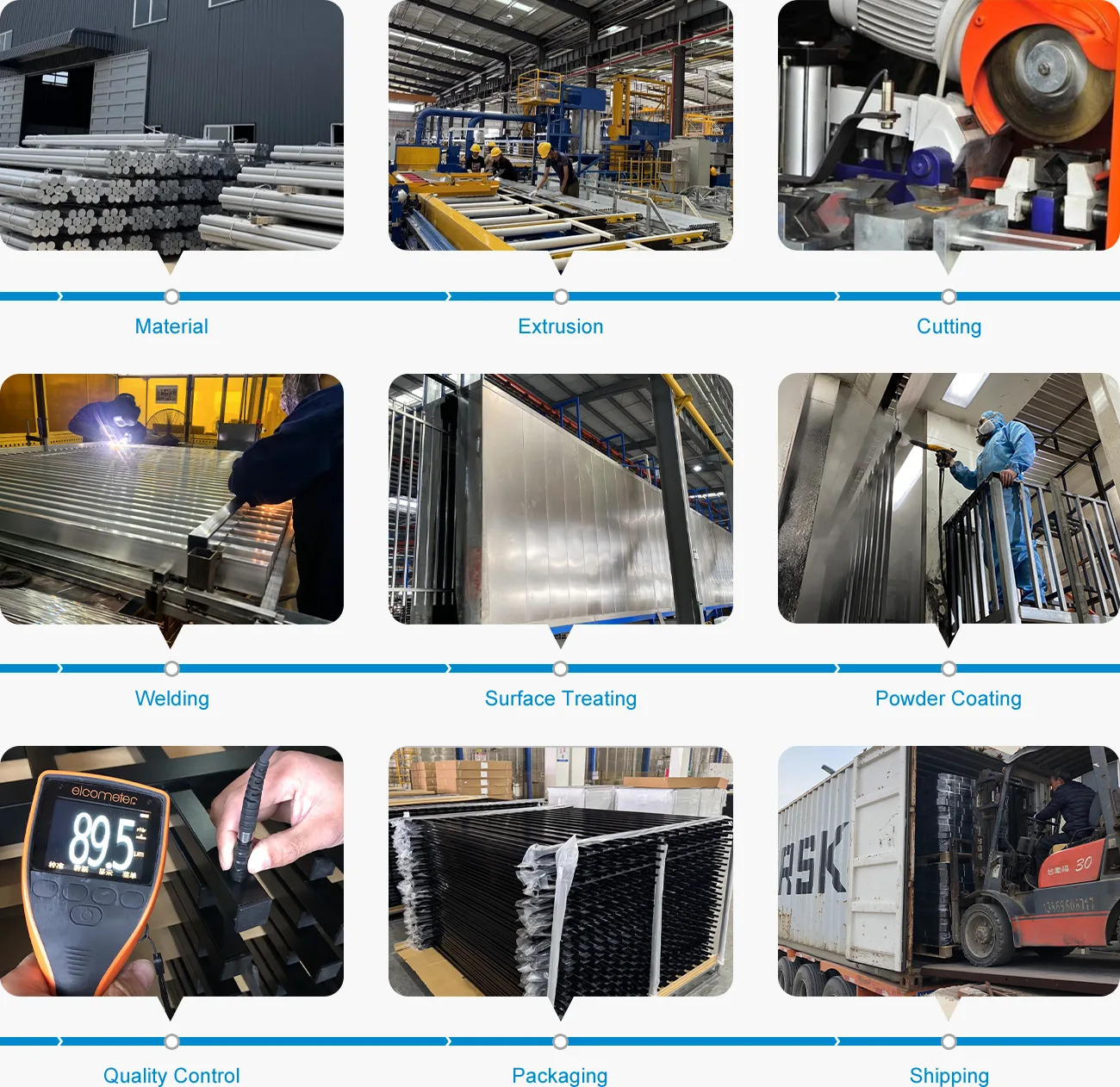

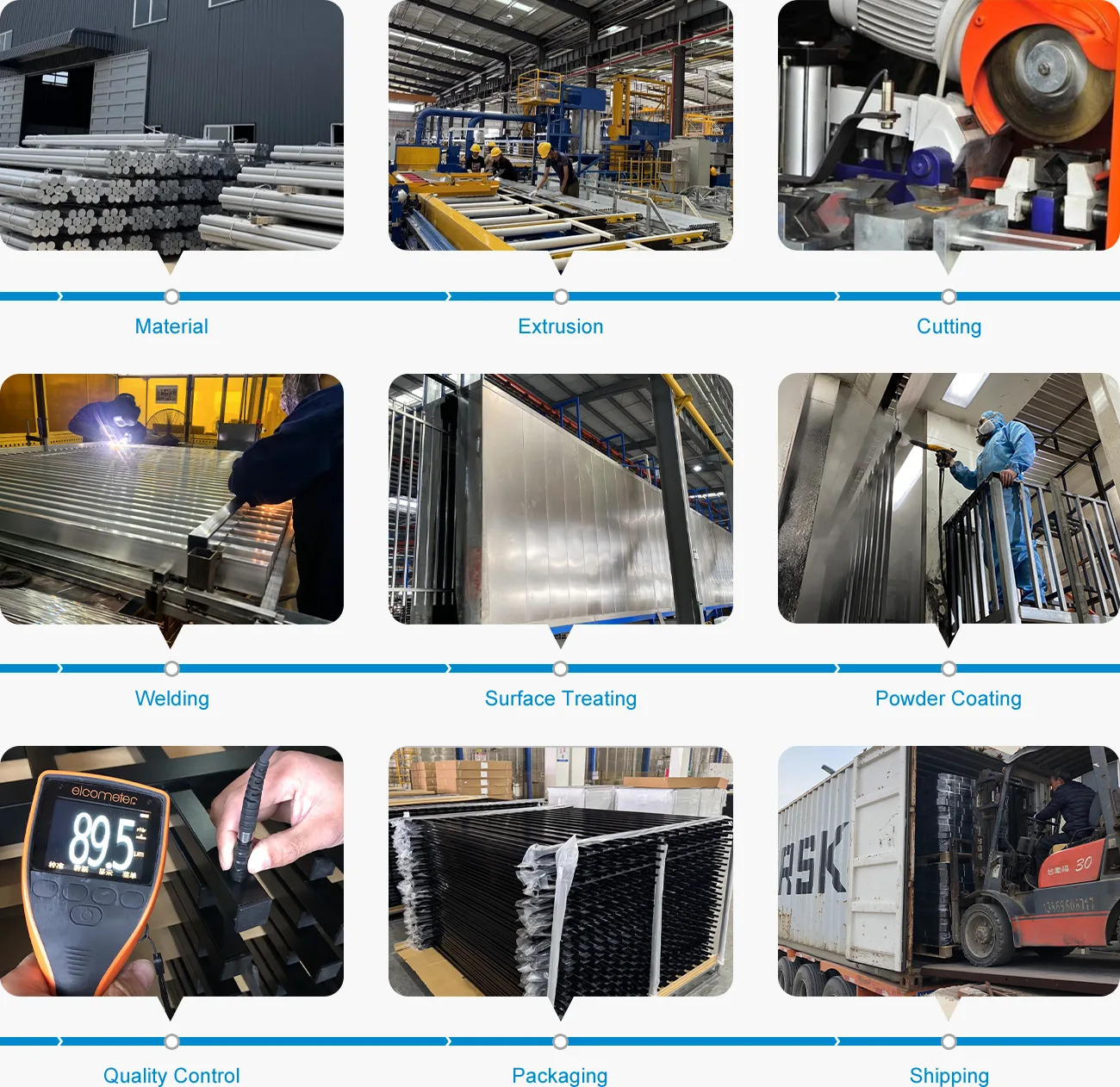

Vertical Blade Fence Gate Production Process

Material

Check the outer diameter and wall thickness of the pipe to ensure that it meets the requirements of the product drawing, thus ensuring quality.

Extrusion

Heat the aluminum rod, pass it through the extruder through the mold, and obtain the required shape.

Cutting

Product unloading, cutting the profile according to the design requirements to obtain the required length.

Welding

Pre-galvanized steel pipes are welded into the panel frame using sophisticated welding techniques.

Surface Treating

The purpose of this operation is to remove welding slag to facilitate the next step.

Powder Coating

This process makes the product’s paint film thickness at least ≥80μm, and can make the product more rust-proof and corrosion-resistant, so it can withstand the erosion of various harsh environments.

Quality Control

We will conduct a quality inspection on each product to ensure the quality stability of each product.

Packaging

Professional transport methods ensure the safe transportation of products.

Shipping

We choose safe and reliable sea transportation methods to provide you with convenient, fast, and stable transportation services.

Blade Fence Gate Applications

- Residential garden or pool fencing

- Commercial courtyard entrances

- Coastal property boundaries

- Urban architectural accents

- DIY-friendly security gates

- Boutique hotel or café perimeters

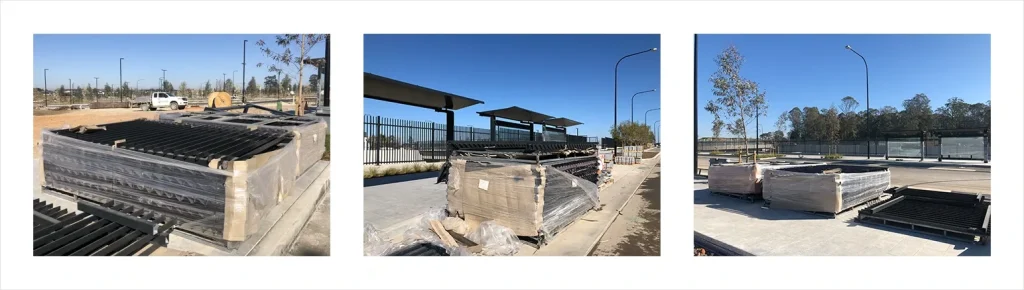

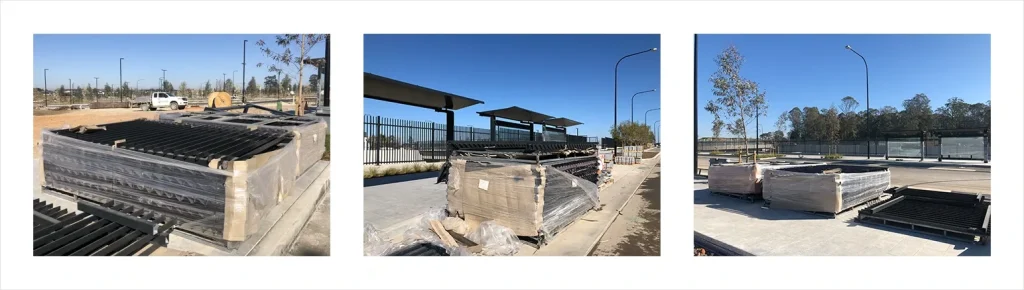

Blade Fence Gate Packaging

- We are well aware of the importance of packaging for the safe transportation of metal vertical slat fence panels.

- Plastic film is used to isolate each board to effectively reduce friction and scratches during transportation.

- Tightly wrapped with stretch film, reinforced with cardboard, and fixed with a steel frame to ensure the stability of the product.

- All pallet loading facilitates forklift operation and improves loading and unloading efficiency.

- We provide flexible packaging solutions. According to your requirements to ensure the safety of the product.

- We choose safe and reliable sea transportation methods to provide you with convenient, fast, and stable transportation services.