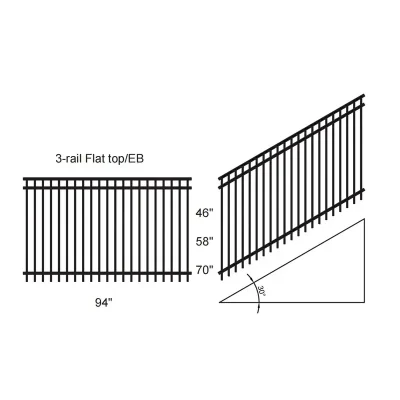

| size (H) inches | size (H) mm | size (W) inches | size (W) mm | Number of Horizontal Rails | Number of Vertical Pickets | Weight (kg.) |

| 34 | 863.6 | 94 | 2387.6 | 2 | 20 | 17.46 |

| 46 | 1168.4 | 94 | 2387.6 | 2 | 20 | 21.05 |

| 58 | 1473.2 | 94 | 2387.6 | 2 | 20 | 24.63 |

| 70 | 1788 | 94 | 2387.6 | 2 | 20 | 28.22 |

| 34 | 863.6 | 94 | 2387.6 | 3 | 20 | 21.12 |

| 46 | 1168.4 | 94 | 2387.6 | 3 | 20 | 24.70 |

| 58 | 1473.2 | 94 | 2387.6 | 3 | 20 | 28.28 |

| 70 | 1788 | 94 | 2387.6 | 3 | 20 | 31.87 |

| Material | Steel or Aluminum | |||||

| Finish | Powder Coating | |||||

| Color | Black, Customized Colors | |||||

| 5/8″picket-18 ga.-15*15*1.2mm | ||||||

| 1-3/16″x 1-5/64″x 1-3/16″rail-14 ga.-30*27.4*30*2.0mm | ||||||

| 94″Panel | ||||||

| Center Distance of Vertical Pickets 116mm | ||||||

| size (H) inches | size (H) mm | size (W) inches | size (W) mm | Number of Horizontal Rails | Number of Vertical Pickets | Weight (kg.) |

| 46 | 1168.4 | 94 | 2387.6 | 2 | 20 | 31.09 |

| 58 | 1473.2 | 94 | 2387.6 | 2 | 20 | 36.39 |

| 70 | 1778 | 94 | 2387.6 | 2 | 20 | 41.70 |

| 82 | 2082.8 | 94 | 2387.6 | 2 | 20 | 47.00 |

| 94 | 2387.6 | 94 | 2387.6 | 2 | 20 | 52.30 |

| 46 | 1168.4 | 94 | 2387.6 | 3 | 20 | 36.08 |

| 58 | 1473.2 | 94 | 2387.6 | 3 | 20 | 41.38 |

| 70 | 1778 | 94 | 2387.6 | 3 | 20 | 46.69 |

| 82 | 1082.8 | 94 | 2387.6 | 3 | 20 | 51.99 |

| 94 | 2387.6 | 94 | 2387.6 | 3 | 20 | 57.29 |

| Material | Steel or Aluminum | |||||

| Finish | Powder Coating | |||||

| Color | Black, Customized Colors | |||||

| 3/4″picket-18 ga.-18*18*1.2mm | ||||||

| 1-9/16″x 1-3/16″x 1-9/16″rail-14 ga.40*30*40*2.0mm | ||||||

| 94″Panel | ||||||

| Center Distance of Vertical Pickets 120mm | ||||||

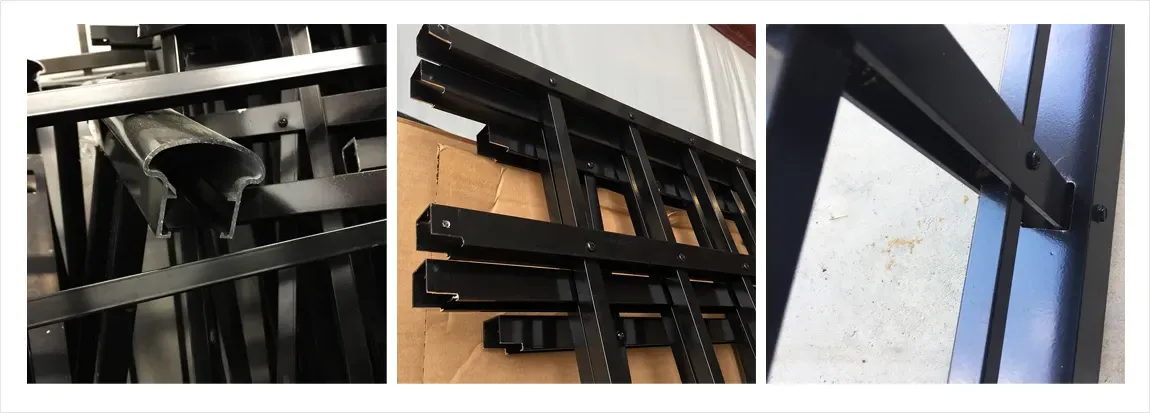

Check the outer diameter and wall thickness of the pipes, to ensure that meets the requirements of the fence drawing, thus ensuring quality.

Product unloading, cutting the profile according to the design requirements to obtain the required length.

Punch holes in the cut pipe.

Assemble the fence panels according to the drawing.

Cleaning and roughening the surface by spraying high-speed abrasive particles. It can remove impurities such as rust, oil, and scale.

The phosphating film itself has a certain anti-corrosion ability and can provide excellent adhesion to paint, powder coating, or other organic coatings.

Spray epoxy-polyester powder on the surface, and cure it at high temperature. This process makes the product more rust-proof and corrosion-resistant.

We will conduct a quality inspection on each product to check the strength, wall thickness, and powder coating thickness to ensure each product’s quality.

Professional transportation methods ensure the safe transportation of products.

For small orders, sample orders, or air shipments, T/T in advance (telegraphic transfer-bank order). We can also offer preferential and flexible payment terms to our customers to establish a win-win partnership. Other payments: L/C, D/A, D/P, MoneyGram, Paypal, or Escrow. There can be minor variations in different places.

We offer the following post-purchase services following your payment:

We have the best after-sales staff around. Please Contact Us as soon as possible if you experience any after-sale issues. We’ll get back to you as soon as we can with a satisfying answer.