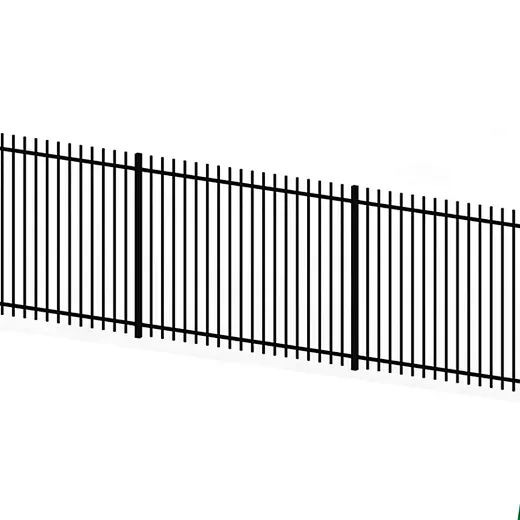

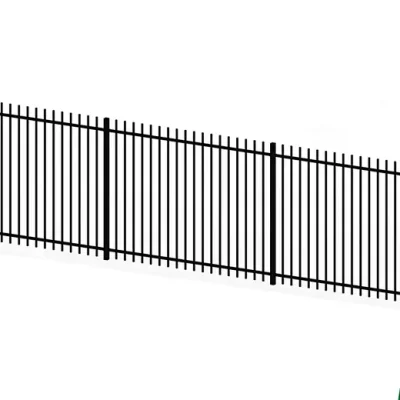

Sinotop Fence’s Rod Top Rackable Fence Panel delivers unmatched adaptability for challenging installations. Designed with extended top and bottom rails, this panel seamlessly adjusts to slopes and uneven terrain through its integrated bracket system. The result is a uniform, visually consistent barrier that maintains structural integrity across diverse landscapes.

Our fence panels are meticulously crafted from structural-grade hot-dip galvanized steel tubing and then subjected to a multi-layer electrostatic powder coating process. This double-layer protection offers outstanding resistance against corrosion, UV rays, and harsh weather conditions. As a result, they are well-suited for long-term outdoor use in residential, commercial, and industrial settings.

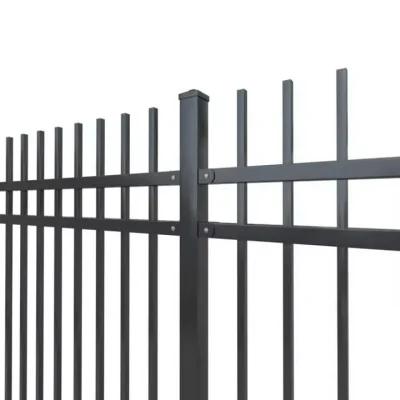

Additionally, we pre-assemble panels with anti-tamper fasteners, post brackets, and caps to streamline installation. Standard dimensions of 2400mm in width and 860mm–2400mm in height, combined with a 1.2mm minimum wall thickness, provide robust security while accommodating site-specific needs. For high-risk areas, wall thickness can be customized up to 2.0mm.

As a trusted manufacturer, Sinotop Fence further supports specialized projects with tailored designs. Our team collaborates closely with clients to meet regional safety regulations and aesthetic preferences, ensuring every solution balances functionality with seamless integration into its surroundings.

| size (H) inches | size (H) mm | size (W) inches | size (W) mm | Number of Horizontal Rails | Number of Vertical Pickets | Weight (kg.) |

| 34 | 863.6 | 94 | 2387.6 | 2 | 20 | 17.46 |

| 46 | 1168.4 | 94 | 2387.6 | 2 | 20 | 21.05 |

| 58 | 1473.2 | 94 | 2387.6 | 2 | 20 | 24.63 |

| 70 | 1778 | 94 | 2387.6 | 2 | 20 | 28.22 |

| Material | Steel or Aluminum | |||||

| Finish | Powder Coating | |||||

| Color | Black, Customized Colors | |||||

| 5/8″picket-18 ga.-15*15*1.2mm | ||||||

| 1-3/16″x 1-5/64″x 1-3/16″rail-14 ga.-30*27.4*30*2.0mm | ||||||

| 94″Panel | ||||||

| Center Distance of Vertical Pickets 116mm | ||||||

| size (H) inches | size (H) mm | size (W) inches | size (W) mm | Number of Horizontal Rails | Number of Vertical Pickets | Weight (kg.) |

| 46 | 1168.4 | 94 | 2387.6 | 2 | 20 | 31.09 |

| 58 | 1473.2 | 94 | 2387.6 | 2 | 20 | 36.39 |

| 70 | 1778 | 94 | 2387.6 | 2 | 20 | 41.70 |

| 82 | 2082.8 | 94 | 2387.6 | 2 | 20 | 47.00 |

| 94 | 2387.6 | 94 | 2387.6 | 2 | 20 | 52.30 |

| Material | Steel or Aluminum | |||||

| Finish | Powder Coating | |||||

| Color | Black, Customized Colors | |||||

| 3/4″picket-18 ga.-18*18*1.2mm | ||||||

| 1-9/16″x 1-3/16″x 1-9/16″rail-14 ga.40*30*40*2.0mm | ||||||

| 94″Panel | ||||||

| Center Distance of Vertical Pickets 120mm | ||||||

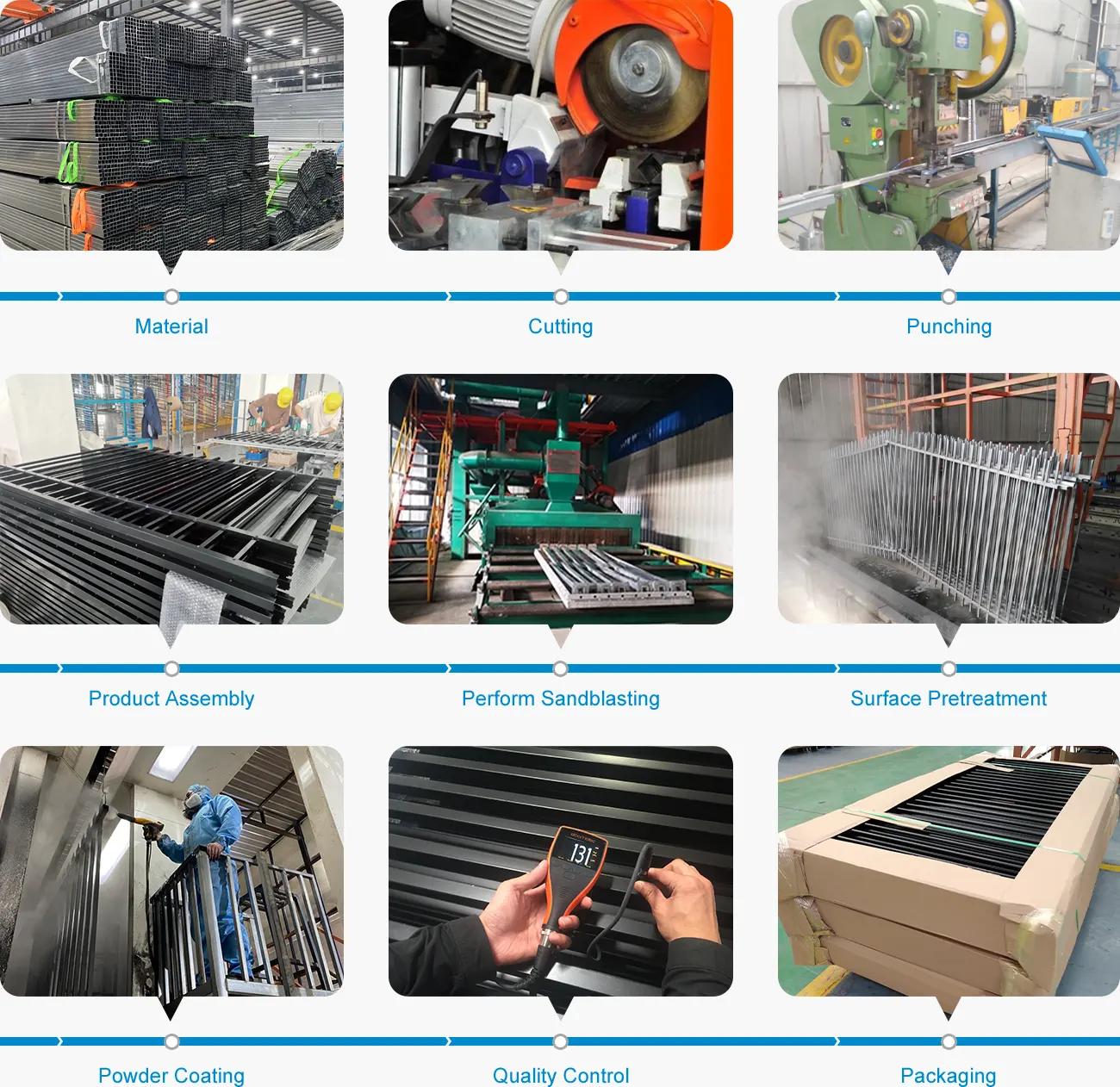

Before commencing production, thoroughly examine the outer diameter and wall thickness of the pipes. This meticulous check ensures that the pipes strictly adhere to the specifications outlined in the fence drawing, thereby guaranteeing the overall quality of the final product.

Once the materials pass inspection, unload the products. Then, precisely cut the profiles according to the detailed design requirements. This step is crucial for obtaining pipes of the exact length needed for the rod top fence.

After cutting the pipes to the required length, proceed to punch holes in them. The punching process is carried out with high precision to ensure that the holes are in the correct positions and of the appropriate size as per the design.

Following the punching step, assemble the fence panels in strict accordance with the provided drawing. Skilled workers carefully fit all the components together, ensuring that each part is correctly positioned and securely attached to create a sturdy fence panel.

To prepare the surface of the assembled fence panels, perform sandblasting. This involves spraying high-speed abrasive particles onto the surface, effectively cleaning and roughening it. Sandblasting removes various impurities such as rust, oil, and scale, which not only improves the appearance but also enhances the adhesion of subsequent coatings.

After sandblasting, carry out surface pretreatment by applying a phosphating process. The phosphating film formed on the surface has inherent anti-corrosion properties and serves as an excellent base for paint, powder coating, or other organic coatings. It significantly improves the adhesion of these coatings, ensuring long-term durability.

Once the surface is properly pretreated, spray epoxy-polyester powder onto the fence panels. After spraying, cure the powder at high temperature. This powder coating process not only gives the fence a smooth and attractive finish but also provides superior rust-proof and corrosion-resistant properties, extending the lifespan of the product.

Before the products leave the production line, conduct a comprehensive quality inspection on each individual rod top fence. Check key parameters such as strength, wall thickness, and powder coating thickness. Only products that meet the strict quality standards are approved for further processing.

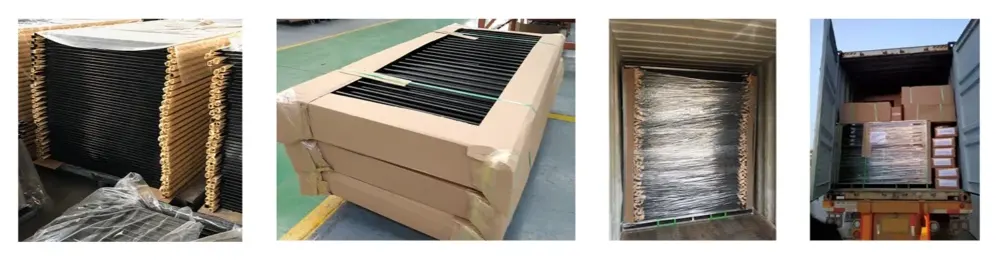

Finally, use professional packaging and transportation methods to ensure the safe delivery of the products. The packaging is designed to protect the fence panels from damage during transit, ensuring that they reach the customers in perfect condition.

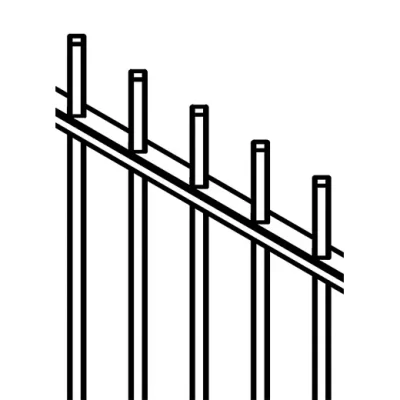

Adjustable bracket system for slopes up to 15° without site modification.

Pre-galvanized steel tubing + multi-layer powder coating (salt spray resistance >1,000 hours).

Wall thickness: 1.2mm (standard), customizable to 2.0mm for high-impact zones.

Pre-assembled post brackets and caps reduce on-site labor by 30%.

Tailored dimensions (height/width); material grades (steel types); powder coating methods (e.g., electrostatic, epoxy); color options (RAL codes or custom samples).

Tamper-resistant fasteners and UV-stable coatings ensure 10+ years of service life.

Designs adaptable to regional safety standards (e.g., anti-climb, load-bearing).

To ensure your order arrives in perfect condition, we employ a robust packaging process.

For small orders, sample orders, or air shipments, T/T in advance (telegraphic transfer-bank order). We can also offer preferential and flexible payment terms to our customers to establish a win-win partnership. Other payments: L/C, D/A, D/P, MoneyGram, Paypal, or Escrow. There can be minor variations in different places.

We offer the following post-purchase services following your payment:

We have the best after-sales staff around. Please Contact Us as soon as possible if you experience any after-sale issues. We’ll get back to you as soon as we can with a satisfying answer.