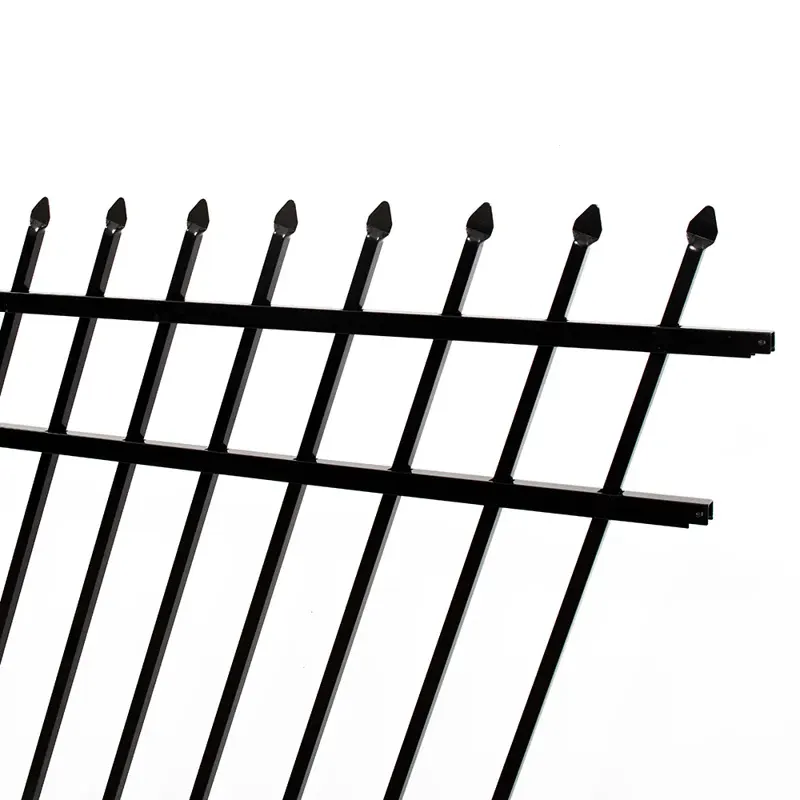

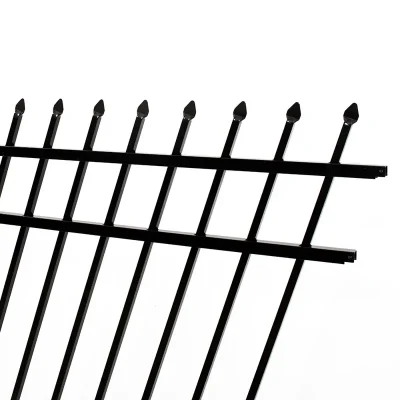

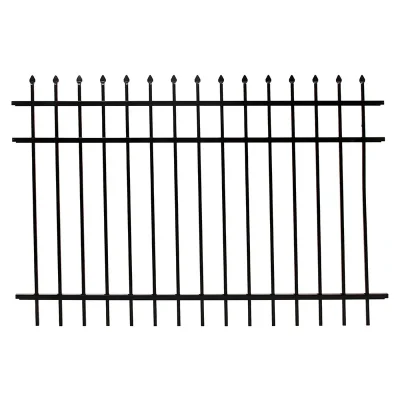

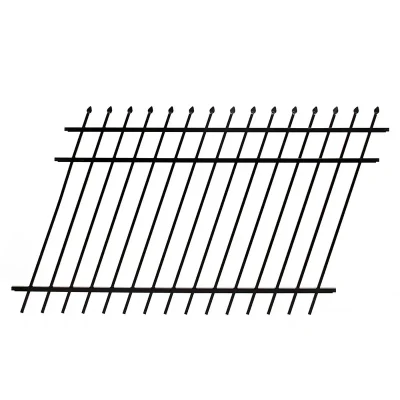

Crafted from premium steel with a rust-resistant powder-coated finish, our Spear Top Rackable Fence blends elegance with durability. The pressed spear-shaped pickets evoke traditional wrought-iron aesthetics while leveraging modern steel strength, creating a boundary solution that is formal yet rugged. Engineered to withstand coastal salt spray, chlorine exposure, and harsh UV rays, its scratch-resistant surface requires virtually no maintenance.

The trestled rackable design adapts to uneven terrain, allowing panels to follow natural landscape curves without compromising structural integrity. Each 2400 mm-wide panel is offered in heights from 860 mm to 2400 mm, with a standard wall thickness of 1.2 mm (customizable up to 2.0 mm for high-impact zones).

Anti-tamper fasteners and reinforced post brackets ensure robust security for residential, commercial, and light industrial applications, including homes, gardens, playgrounds, and pet enclosures.

As a leading manufacturer, Sinotop Fence provides full customization—from material grades and panel dimensions to powder-coating colors (RAL codes or custom samples). This flexibility enables precise alignment with regional climate demands and architectural styles.

| size (H) inches | size (H) mm | size (W) inches | size (W) mm | Number of Horizontal Rails | Number of Vertical Pickets | Weight (kg.) |

| 34 | 863.6 | 94 | 2387.6 | 3 | 20 | 21.12 |

| 46 | 1168.4 | 94 | 2387.6 | 3 | 20 | 24.70 |

| 58 | 1473.2 | 94 | 2387.6 | 3 | 20 | 28.28 |

| 70 | 1778 | 94 | 2387.6 | 3 | 20 | 31.87 |

| Material | Steel or Aluminum | |||||

| Finish | Powder Coating | |||||

| Color | Black, Customized Colors | |||||

| 5/8″ picket-18 ga.-15*15*1.2mm | ||||||

| 1-3/16″x 1-5/64″x 1-3/16″rail-14 ga.-30*27.4*30*2.0mm | ||||||

| 94″ Panel | ||||||

| Center Distance of Vertical Pickets 116mm | ||||||

| size (H) inches | size (H) mm | size (W) inches | size (W) mm | Number of Horizontal Rails | Number of Vertical Pickets | Weight (kg.) |

| 46 | 1168.4 | 94 | 2387.6 | 3 | 20 | 36.08 |

| 58 | 1473.2 | 94 | 2387.6 | 3 | 20 | 41.38 |

| 70 | 1778 | 94 | 2387.6 | 3 | 20 | 46.69 |

| 82 | 2082.8 | 94 | 2387.6 | 3 | 20 | 51.99 |

| 94 | 2387.7 | 94 | 2387.6 | 3 | 20 | 57.29 |

| Material | Steel or Aluminum | |||||

| Finish | Powder Coating | |||||

| Color | Black, Customized Colors | |||||

| 3/4″picket-18 ga.-18*18*1.2mm | ||||||

| 1-9/16″x 1-3/16″x 1-9/16″rail-14 ga.40*30*40*2.0mm | ||||||

| 94″ Panel | ||||||

| Center Distance of Vertical Pickets 120mm | ||||||

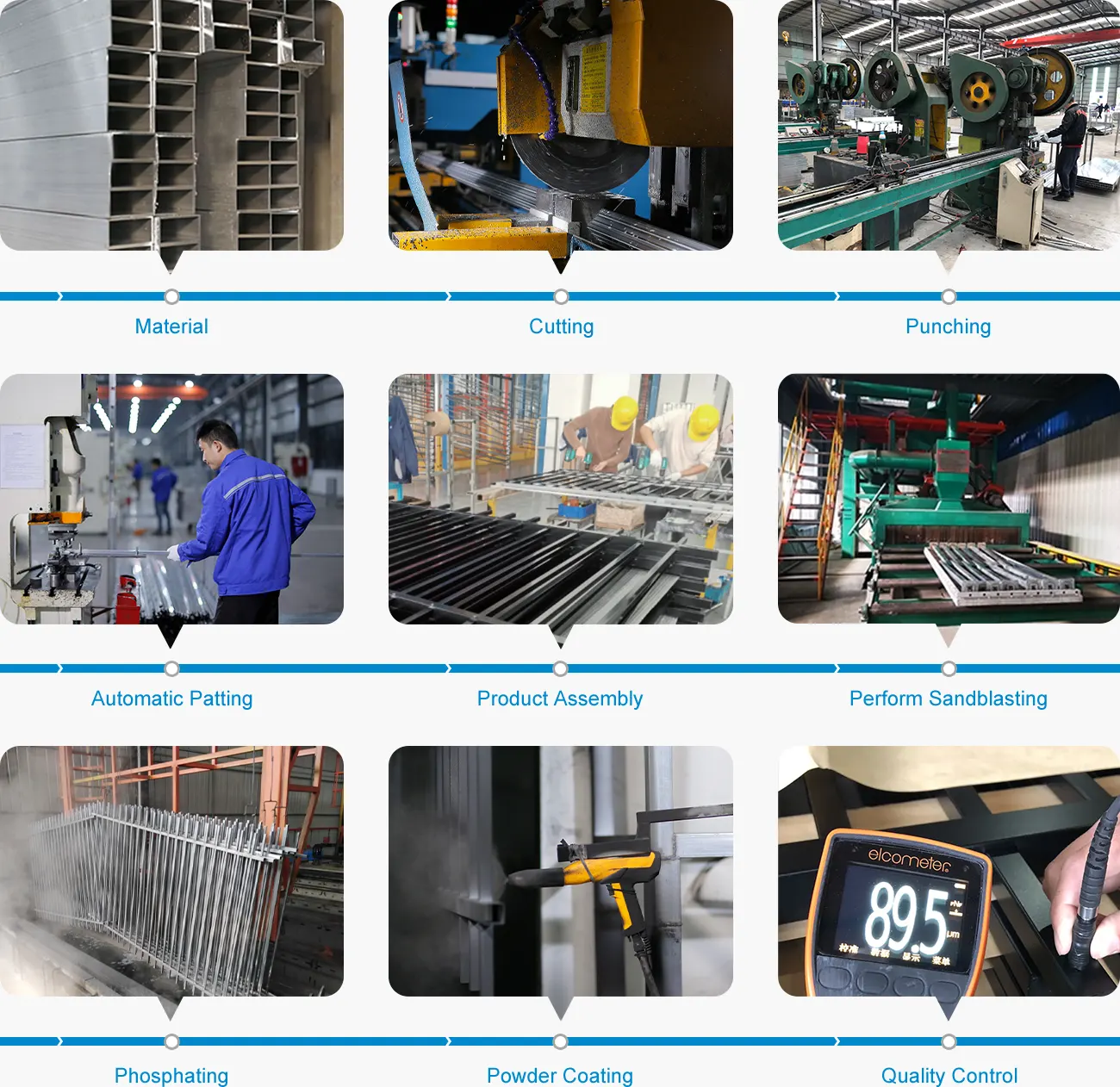

We start with a meticulous material inspection process. For the pipes used in the fence, we measure the outer diameter and wall thickness with high-precision measuring tools. The outer diameter should be within an accuracy range of ±0.1mm, and the wall thickness should be maintained with a tolerance of ±0.05mm to strictly meet the requirements of the fence drawing.

Once the materials pass the inspection, the product unloading begins. Using advanced cutting equipment, we cut the profiles according to the design requirements. The cutting length accuracy is controlled within ±1mm.

After cutting, we proceed to the punching stage. Specialized punching machines are used to create holes in the cut pipes. The hole diameter has an accuracy of ±0.08mm, and the hole spacing is maintained with a tolerance of ±0.2mm.

In this step, automated machinery takes center stage. The machinery uses a controlled cutting process to shape the picket tops into uniform spear profiles. The shaping process has a precision of ±0.06mm in terms of the spear’s dimensions. The automated machinery can process 5 – 8 pickets per minute, ensuring high-volume and consistent production.

Following the shaping, we assemble the fence panels according to the detailed drawing. The assembly process requires workers to follow strict procedures. The alignment of components has an accuracy of ±0.3mm, and the connection strength between parts should be able to withstand a pulling force of at least 500N.

The assembled fence panels then undergo sandblasting. We use high-pressure equipment to spray high-speed abrasive particles at a pressure of 0.5 – 0.7MPa. The abrasive particles have a size range of 0.5 – 1.5mm. This process not only effectively removes impurities such as rust, oil, and scale but also roughens the surface to a roughness of Ra 3.2 – 6.3μm, which is ideal for subsequent surface treatments.

After sandblasting, the fence panels are subjected to surface pretreatment. We immerse the panels in a phosphating solution for 15 – 20 minutes at a temperature of 40 – 50°C. The phosphating film formed has a thickness of 2 – 5μm. This film not only has a certain anti-corrosion ability but also provides excellent adhesion for the subsequent powder coating.

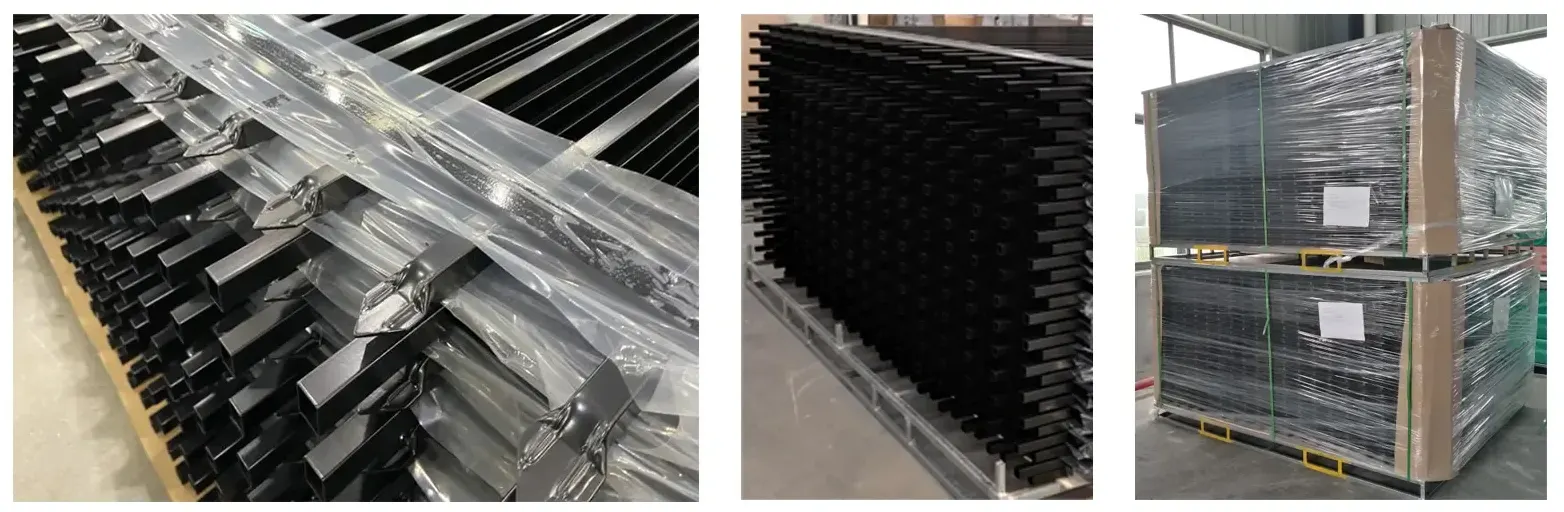

We spray epoxy-polyester powder on the pretreated surface using electrostatic spraying equipment. The powder coating thickness is controlled within the range of 60 – 80μm. After spraying, the fence panels are cured in a high-temperature oven at 180 – 200°C for 15 – 20 minutes. This process significantly enhances the rust-proof and corrosion-resistant properties of the product.

Finally, we conduct a comprehensive quality inspection on each product. We use non-destructive testing methods to check the strength, wall thickness, and powder coating thickness. The strength test requires the fence to withstand a lateral force of at least 800N without significant deformation.

For small orders, sample orders, or air shipments, T/T in advance (telegraphic transfer-bank order). We can also offer preferential and flexible payment terms to our customers to establish a win-win partnership. Other payments: L/C, D/A, D/P, MoneyGram, Paypal, or Escrow. There can be minor variations in different places.

We offer the following post-purchase services following your payment:

We have the best after-sales staff around. Please Contact Us as soon as possible if you experience any after-sale issues. We’ll get back to you as soon as we can with a satisfying answer.