Sinotop Fence offers commercial and industrial metal electric steel sliding gates, which are an ideal solution for establishing a secure entry and exit point. The sliding gates feature a classic spear top design, commonly referred to as spear top gates. It can be used in conjunction with our garrison fence, spear top fence, or other commercial security fence products.

These gates are not only robust and dependable but also come with low maintenance costs. We utilize galvanized steel that undergoes chemical treatment. This treatment effectively prevents rust and corrosion, making it an extremely durable material for our metal sliding gates.

Additionally, we employ a powder coating system in the production of our steel sliding gates. This is the optimal process for protecting the product from rust and corrosion. Powder coating not only boosts the product’s durability but also enhances its visual appeal.

Installing steel sliding gates can safeguard property and personal safety in both commercial areas and residential homes. These gates can be connected to a power source, enabling a higher level of automation. They effectively prevent unauthorized entry, thereby enhancing security. Thanks to their versatility, they are suitable for any area requiring security.

Our spear top gates are available in a wide range of specifications to meet different usage scenarios. Moreover, we offer customization services based on the specific area of use or other customer requirements.

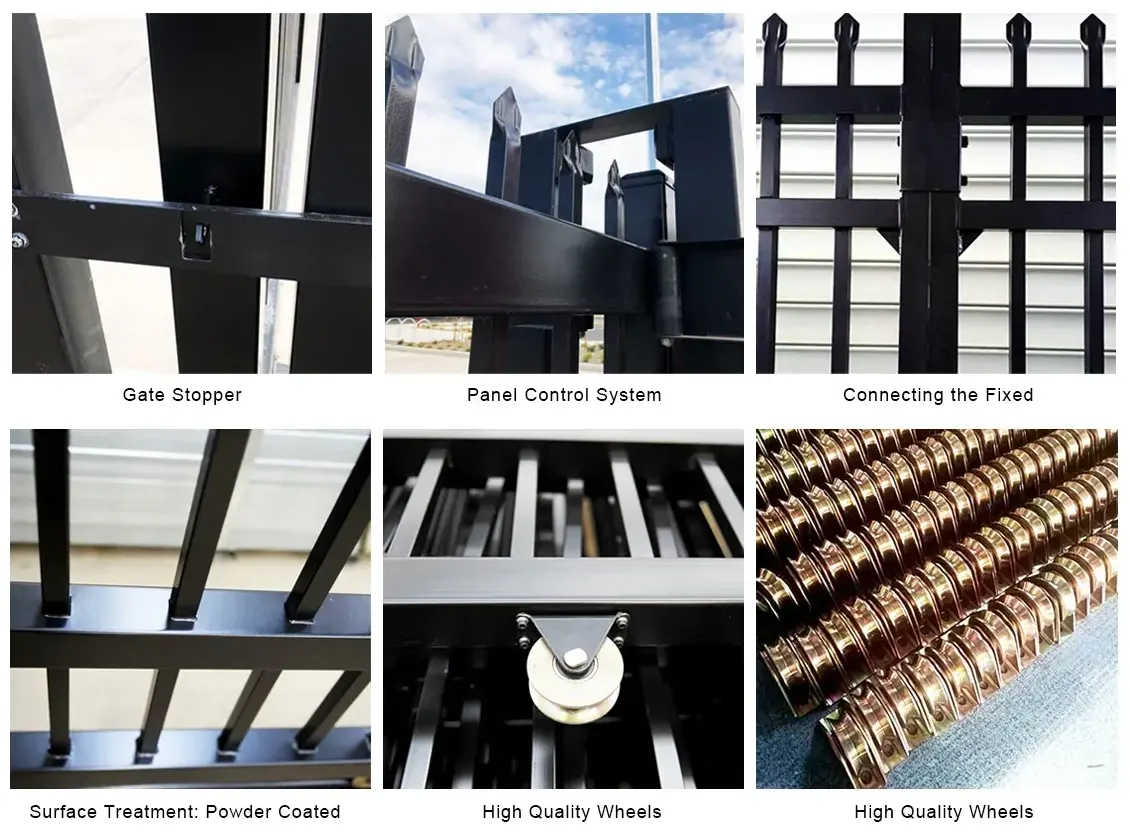

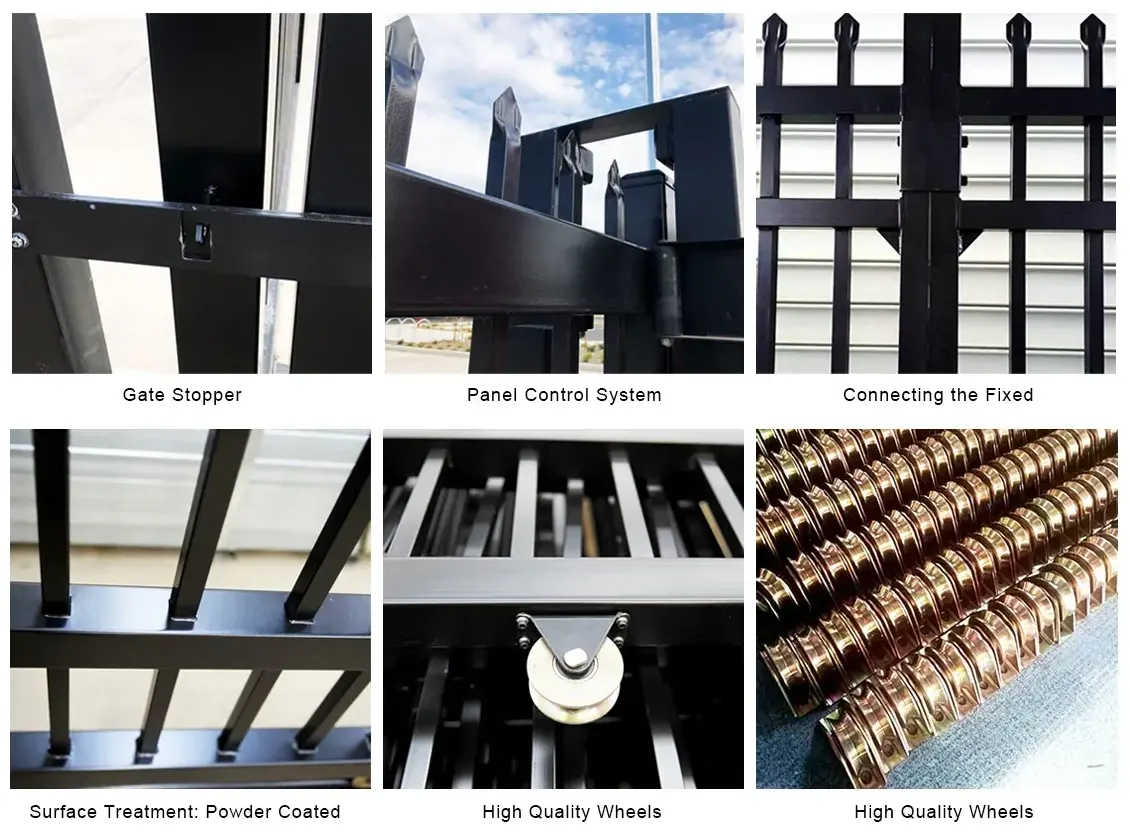

Metal Steel Sliding Gate Details

- Material Options: Galvanized steel or aluminum is available, offering excellent corrosion resistance and strength, suitable for a variety of environmental conditions.

- Surface Treatment: A black powder coat not only enhances the appearance but also provides increased weather and corrosion resistance, extending the service life.

- Security: Steel sliding gates are equipped with locks, stoppers, wheels, and a security system to ensure security during off-hours.

- Operation: You can choose between manual and electric operation. Electric sliding doors offer increased convenience and are ideal for frequently used locations.

- Custom Sizes: Steel sliding gates can be customized to meet your specific needs, ensuring a perfect fit for any opening.

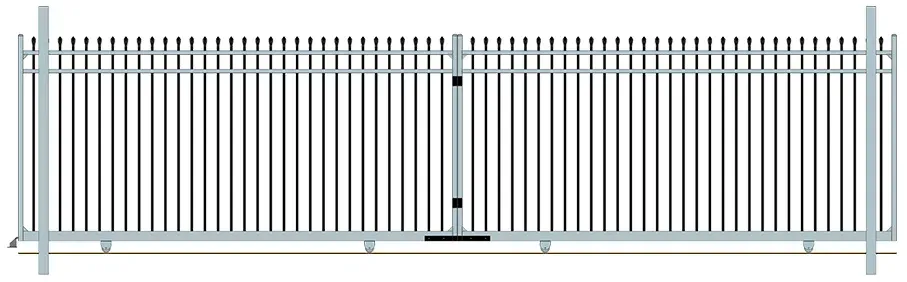

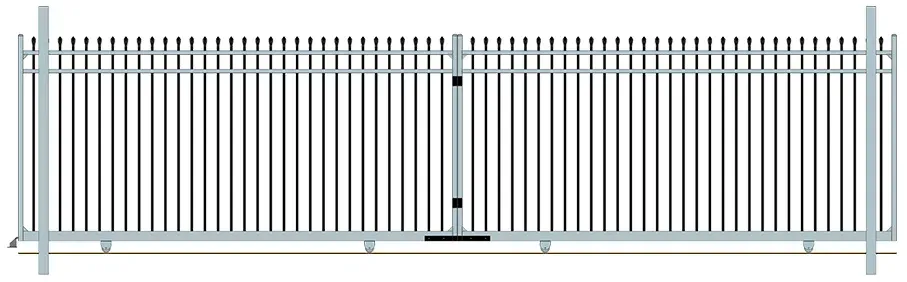

Metal Steel Sliding Gate Drawing

If you are looking for durable and high-quality electric metal sliding gate products, please do not hesitate to contact us.

Spear Top Gate Specifications

| Name |

Project |

| 5m electric sliding gates (2100mm x 5000mm) |

Bottom frame tube specification |

Quantity and length |

Outer frame tube specification |

Quantity |

Material |

| 100x50x3 |

1×4900 |

50x50x1.6 |

2×2100 |

Aluminum |

| Beam specification |

Quantity |

Standpipe Specifications |

Quantity |

| 40x40x1.6 |

3×4900 |

25x25x1.2 |

36×2020 |

| 7m electric sliding gates (2100mm x 7000mm) |

Bottom frame tube specification |

Quantity and length |

Outer frame tube specification |

Quantity |

Material |

| 100x50x3 |

1×3500 |

50x50x3 |

2×2100 |

Aluminum |

| Beam specification |

Quantity |

Standpipe Specifications |

Quantity |

| 50x50x3 |

3×3400 |

25x25x1.2 |

24×2020 |

| 7.5m electric sliding gates (2100mm x 7500mm) |

Bottom frame tube specification |

Quantity and length |

Outer frame tube specification |

Quantity |

Material |

| 100x50x3 |

1×3750 |

50x50x3 |

2×2100 |

Aluminum |

| Beam specification |

Quantity |

Standpipe Specifications |

Quantity |

| 50x50x3 |

3×3650 |

25x25x1.2 |

26×2020 |

| 9m electric sliding gates (2100mm x 9000mm) |

Bottom frame tube specification |

Quantity and length |

Outer frame tube specification |

Quantity |

Material |

| 100x50x3 |

1×4500 |

50x50x3 |

2×2100 |

Aluminum |

| Beam specification |

Quantity |

Standpipe Specifications |

Quantity |

| 50x50x3 |

3×4400 |

25x25x1.2 |

32×2020 |

| 12m electric sliding gates (2100mm x 12000mm) |

Bottom frame tube specification |

Quantity and length |

Outer frame tube specification |

Quantity |

Material |

| / |

/ |

65x65x2 |

2×2000 |

Galvanized steel |

| Beam specification |

Quantity |

Standpipe Specifications |

Quantity |

| 65x65x2 |

3×2935 |

25x25x1.2 |

23×1935 |

Steel Sliding Gate Customizable Specification List

| Dimensions |

Width, Height, Vertical Pipe Size |

| Square Tube Part |

Outer Diameter, Wall Thickness |

| Material |

Aluminum, Zinc, Steel, or Other |

| Surface Treatment |

Spraying or Other |

| Guide Rail Type |

Flat Push, Hanging |

| Other |

Gate lengths exceeding 6 meters require splicing. |

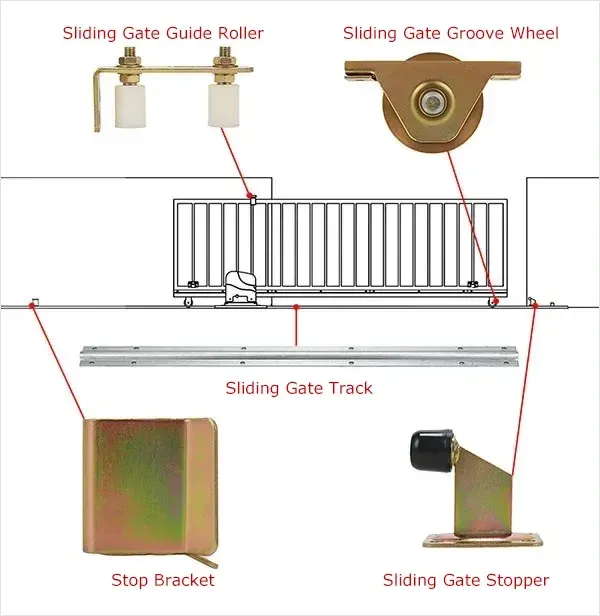

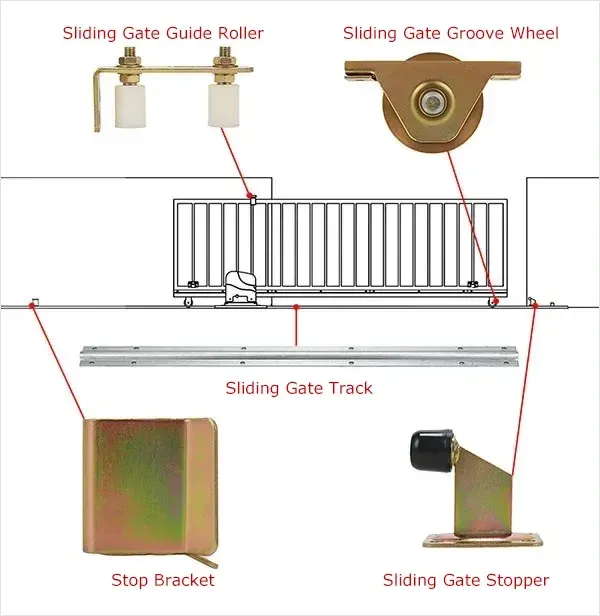

Sliding Gate System Related Components

Use the Guide Roller Kit, Stop Bracket, Roller Wheel Kit, Sliding Gate Track Kit, and Gate Stopper together to form a complete sliding gate system, making it easier, smoother, and more convenient to use.

Metal Steel Sliding Gate Advantages

- Durable and Cost-Effective: This product combines strength, corrosion resistance, and affordability, making it the perfect choice for both commercial and industrial properties.

- Versatile Material Choices: Offered in both galvanized steel and aluminum, our products provide flexible material options tailored to your specific requirements.

- Simple DIY Installation: Engineered for easy DIY installation, this high-quality product presents a convenient and budget-friendly solution for property owners.

- Sleek Black Powder Coating: Featuring a stylish black powder coating, the gate not only enhances its aesthetic appeal but also offers superior protection against corrosion and weather elements.

- Weld-Free Design: Our innovative weld-free metal sliding gate design eliminates the need for welding during installation, ensuring a safer and more efficient process.

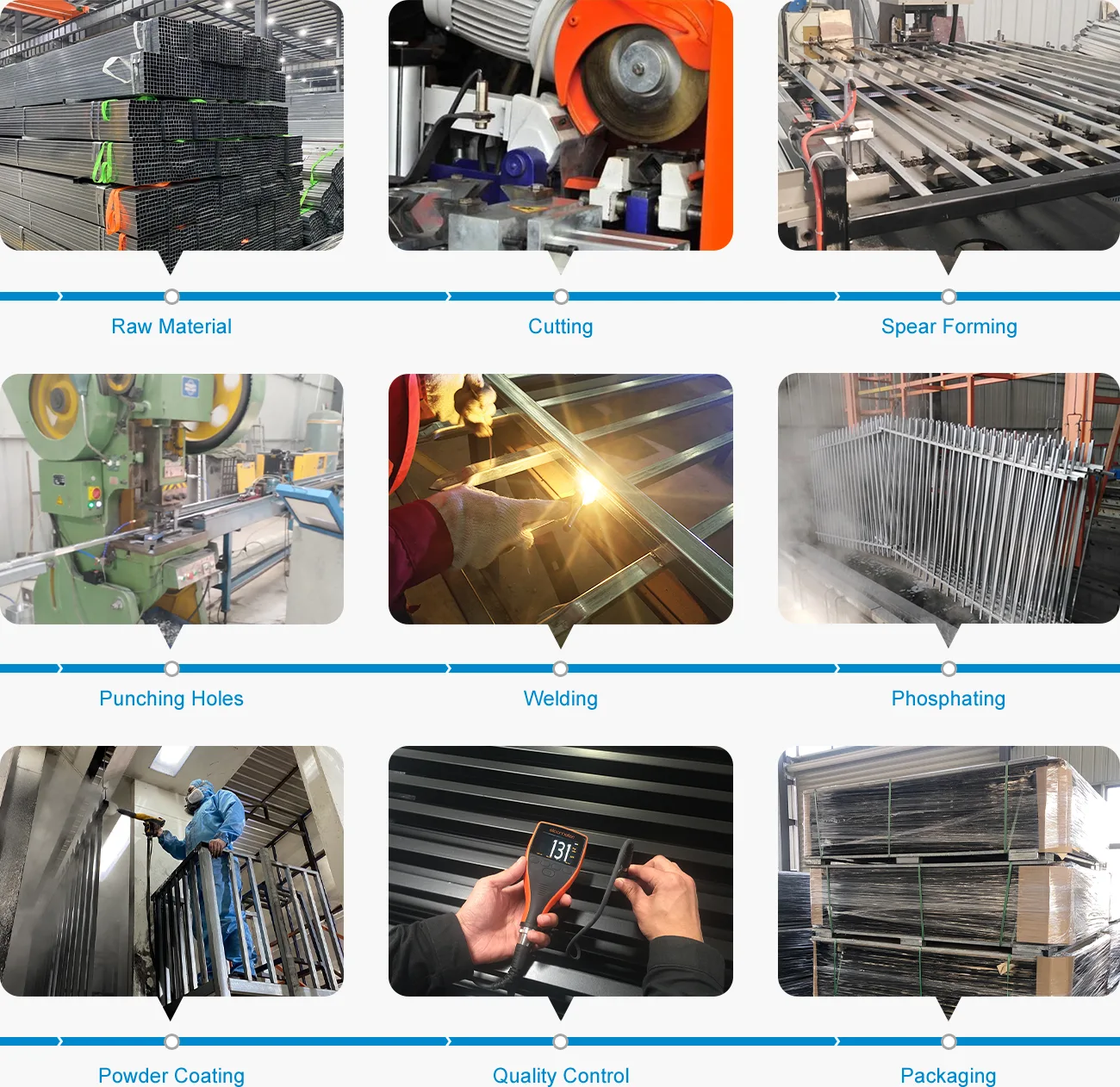

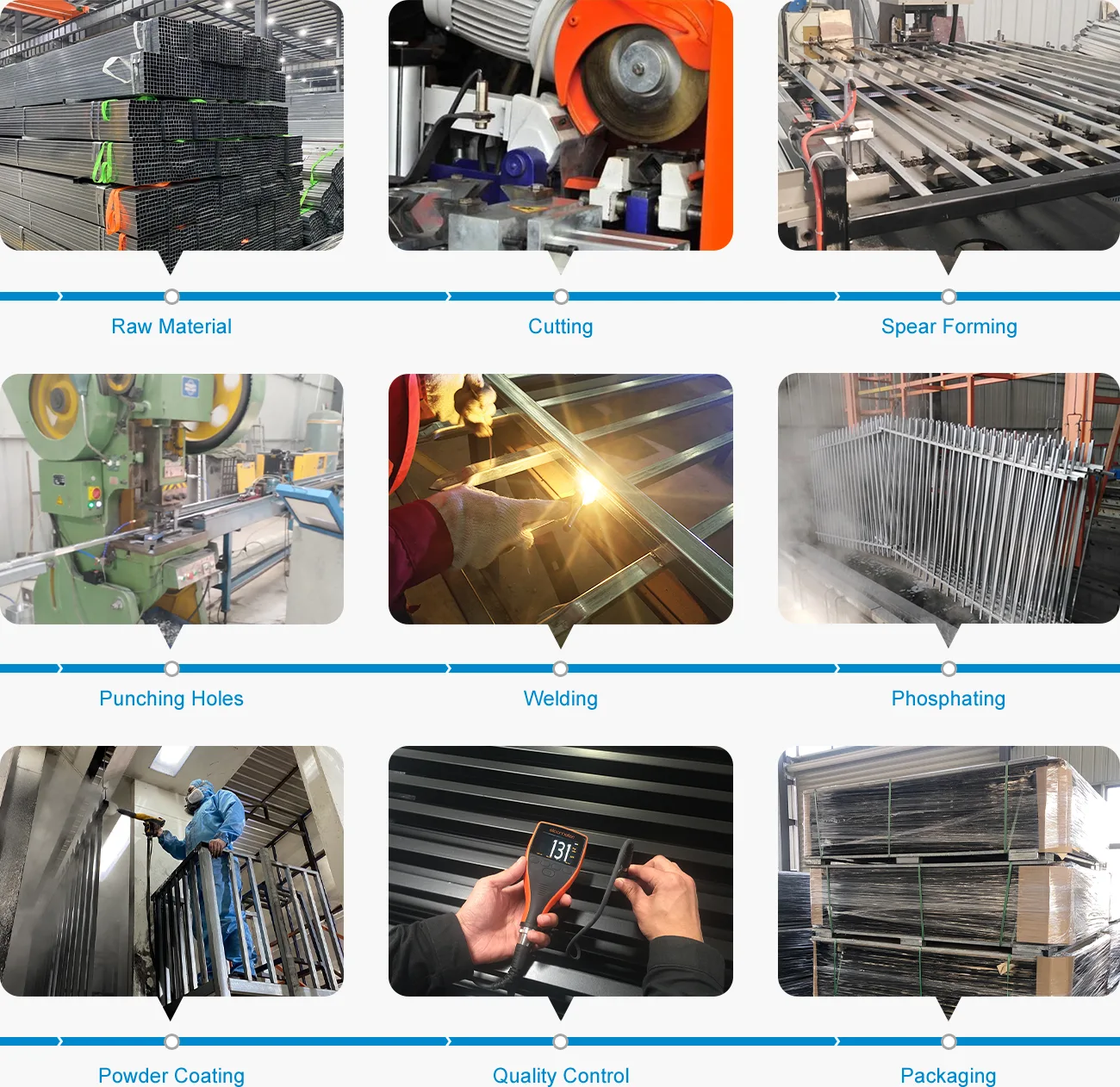

Steel Sliding Gate Production Process

Raw Material

Before commencing the production process, a meticulous inspection of the raw material-the pipe-is carried out. Special attention is paid to two crucial dimensions: the outer diameter and the wall thickness. These parameters are carefully measured and compared against the precise specifications outlined in the product drawing.

Cutting

Once the raw material has passed the inspection, the cutting process begins. The pipes are precisely cut according to the length requirements specified in the product drawing. Advanced cutting equipment is employed to ensure high-precision cuts, minimizing any deviations from the specified lengths.

Spear Forming

In this stage, the top part of the pipe undergoes a specialized forming process. The pipe’s top is carefully flattened and then subjected to a squeezing operation. Through this series of actions, the pipe’s end is transformed into the distinctive spear-shaped pressed spears that are characteristic of the sliding gate.

Punching Holes

To facilitate the subsequent assembly and installation operations, pre-punching holes is made in the beam using dedicated equipment. These holes are drilled with high precision, following the layout and dimensions specified in the design.

Welding

The pre-galvanized steel pipes are then carefully spliced together to form frames. The welding process is carried out under strict quality control measures to ensure that the welds are strong, durable, and free from defects. This results in a robust frame that can withstand the stresses and strains of regular use.

Phosphating

The purpose of phosphating the surface of the product is to form a dense layer of pits on the surface of the pipe, thus increasing the adhesion of the powder.

Powder Coating

The surface of the product is sprayed with epoxy-polyester powder and cured at high temperatures. This process makes the product’s paint film thickness at least ≥80μm. This process can make the product more rust-proof and corrosion-resistant, so it can withstand the erosion of various harsh environments.

Quality Control

We will conduct a quality inspection on each piece of powder-coating metal steel sliding driveway gate to check the strength, wall thickness, and powder-coating thickness to ensure the quality stability of each product. We will be responsible for every product so that customers can get the best quality products.

Packaging

The product is first wrapped with wrapping film, which provides a protective layer against scratches and minor impacts. Then, cardboard is placed around the product to add additional cushioning and structural support. Finally, strapping tape is used to secure the packaging, preventing the product from shifting during transit.

Steel Sliding Gate Application

- Commercial Properties: Steel sliding gates are commonly used in shopping malls, warehouses, and industrial parks, providing secure entrances and exits to prevent unauthorized entry.

- Residential Properties: Many residential complexes and single-family homes choose steel sliding gates for driveway entrances, offering both aesthetic appeal and effective protection.

- Public Facilities: Public spaces such as schools, hospitals, and parks also frequently utilize steel sliding gates to ensure safe and convenient access.

Spear Top Sliding Gate Packaging

- Packaging is very important for the safe transportation of metal sliding gates.

- We use stretch film + strapping + four-corner cardboard + pallet + steel frame packaging to protect the product to the greatest extent.

- At the same time, our customers can unload the product easily. If you have other needs, we will strictly follow your requirements for packaging.

- We use sea transportation, which is convenient, fast, and stable.